Stable commitment to every leap, customized every flat

Blog

Stable commitment to every leap, customized every flat

Blog

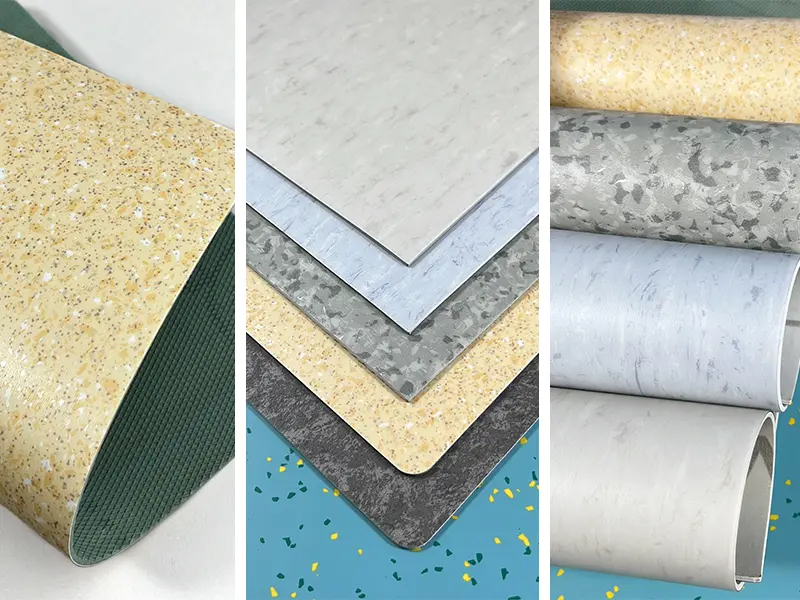

When selecting PVC commercial vinyl flooring for spaces like offices, hospitals, schools, or retail stores, two primary types dominate the market: heterogeneous vinyl flooring (multi-layered) and homogeneous vinyl flooring (single-layer, through-color). While both are durable, non-toxic, and suitable for high-traffic areas, their structural designs create distinct differences in performance, appearance, and ideal applications. This guide breaks down these differences in detail—helping architects, facility managers, and procurement teams make informed decisions aligned with their space’s unique needs.

Before diving into differences, it’s critical to understand their foundational designs—this is where most distinctions originate.

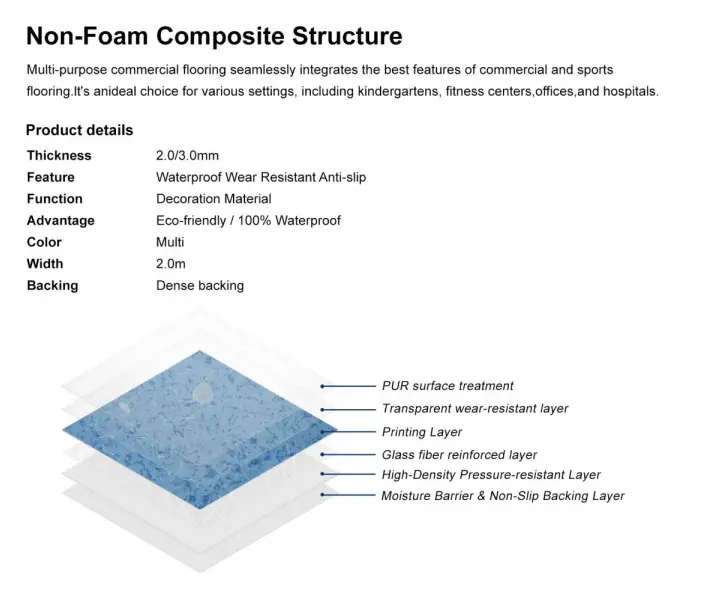

Derived from the Greek “hetero” (different) + “genos” (kind), heterogeneous vinyl is a multi-layered flooring solution. It consists of 3–5 distinct layers, each engineered to serve a specific function (e.g., wear resistance, aesthetics, cushioning). These layers are bonded together under high heat and pressure to form a unified sheet or tile. It’s the most common commercial vinyl flooring, valued for its versatility and balanced performance.

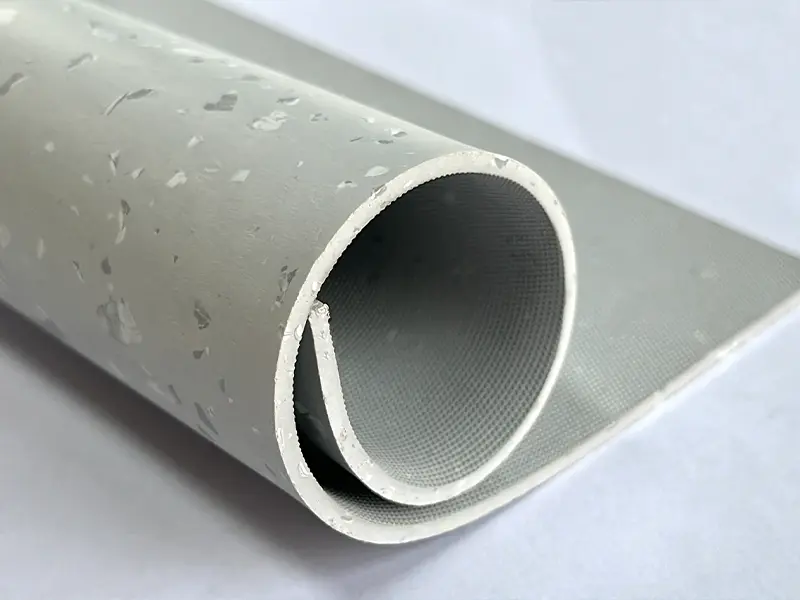

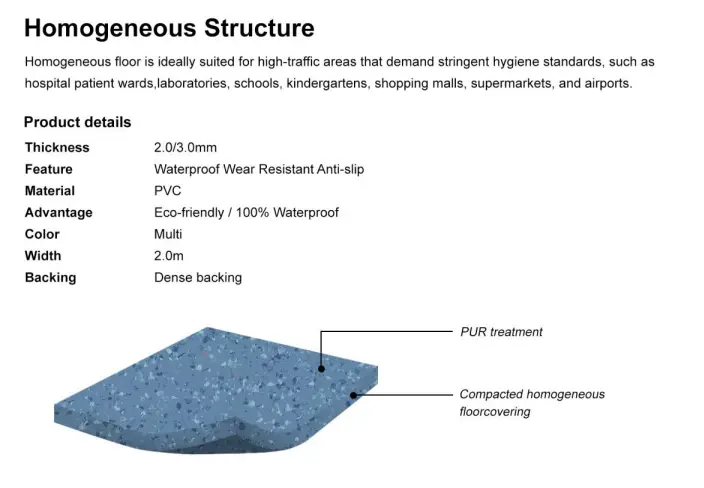

From the Greek “homo” (same) + “genos” (kind), homogeneous vinyl is a single-layer flooring material. Its color, texture, and performance properties are uniform throughout the entire thickness—there are no separate “wear layers” or “decorative layers.” It’s made by mixing PVC resin, colorants, stabilizers, and reinforcing agents into a homogeneous compound, then extruded or pressed into sheets/tile. It excels in high-wear, high-hygiene environments where longevity and consistency are non-negotiable.

The core distinction between the two lies in their structure—a factor that directly impacts durability, flexibility, and maintenance.

Heterogeneous flooring typically includes 4–5 layers, each with a targeted role (see table below). This layered design allows manufacturers to tailor performance to specific needs (e.g., adding cushioning for offices or extra wear resistance for retail).

Layer Name | Material & Thickness | Primary Function |

Wear Layer (Top Layer) | 0.15–0.5mm PU/PUR or Reinforced PVC | Resists scratches, scuffs, and UV fading. Thicker layers (0.3–0.5mm) suit high-traffic areas; thinner (0.15–0.2mm) for low-traffic spaces. |

Decorative Layer | 0.05–0.1mm Printed PVC Film | Delivers aesthetics: mimics wood, stone, tile, or custom patterns (e.g., brand logos). Ink is UV-stabilized to prevent fading. |

Core Layer (Dense PVC) | 2.0–4.0mm High-Density PVC (1.6–1.8g/cm³) | Provides structural stability, impact resistance, and moderate cushioning. May include fiberglass mesh to reduce warping. |

Cushion/Comfort Layer (Optional) | 0.5–1.5mm EVA Foam or Flexible PVC | Adds foot comfort (critical for offices/schools where people stand/walk for hours) and sound absorption (reduces noise by 15–22dB). |

Backing Layer | 0.2–0.3mm PVC or Fiberglass | Enhances moisture resistance (prevents subfloor dampness from seeping up) and dimensional stability (avoids shrinking/expanding with temperature changes). |

Homogeneous flooring has no distinct layers—its composition is consistent from top to bottom. The typical formula includes:

• 60–70% PVC resin (base material for durability);

• 10–15% plasticizers (adds flexibility, though less than heterogeneous);

• 10–15% fillers (calcium carbonate, for strength without excess weight);

• 5–10% colorants (organic/inorganic pigments, mixed into the compound—not printed on top);

• 1–2% stabilizers (prevents degradation from heat/UV).

Thickness ranges from 1.5–4.0mm, with 2.0–3.0mm being standard for commercial use. Some variants include a thin fiberglass mesh embedded within the material (not as a separate layer) to boost dimensional stability.

Aesthetics are a key consideration for commercial spaces (e.g., retail branding, hospital calmness). The two flooring types differ drastically in how they achieve color and texture.

• Pattern Variety: The decorative layer uses high-resolution printing to mimic natural materials (oak, marble, travertine) or create custom designs (geometric patterns, company colors). This makes it ideal for spaces where aesthetics align with brand identity (e.g., a boutique using marble-look vinyl) or need to feel warm (e.g., a school with wood-look vinyl).

• Texture Options: Surface textures (matte, semi-gloss, embossed) are applied to the wear layer, often matching the printed pattern (e.g.,custom printed vinyl commercial flooring).

• Longevity of Appearance: The decorative layer is under the wear layer, so it remains vibrant as long as the wear layer holds up. However, if the wear layer is severely scratched (exposing the decorative layer), the damage is visible and cannot be repaired—only replaced.

• Color/Texture Consistency: Color and texture are mixed into the material, so they run through the entire thickness. Common looks include solid colors (white, gray, blue), subtle speckled textures, or muted stone-like patterns. Bold prints (e.g., wood grain) are rare, as the homogeneous mix can’t replicate fine details.

• Surface Finish: Typically matte or low-gloss, with textures focused on functionality (e.g., slip-resistant micro-grooves) rather than aesthetics.

• Longevity of Appearance: Even if the surface is scratched or worn down (e.g., from heavy carts), the color and texture remain identical—no “exposed layers” or uneven fading. This makes it ideal for spaces where appearance consistency is critical (e.g., hospitals, where scuffs can’t look unhygienic).

Performance is the make-or-break factor for commercial flooring. Below is a side-by-side comparison of critical metrics:

Performance Metric | Heterogeneous Vinyl Flooring | Homogeneous Vinyl Flooring | Key Takeaway |

Abrasion Resistance | Relies on the wear layer: ISO 10581 Class 3–4 (2,000–4,000 revolutions). Thicker PU/PUR layers (0.3mm+) reach Class 4. | Entire material resists wear: ISO 10581 Class 4–5 (4,000–6,000 revolutions). More durable for extreme traffic. | Homogeneous is better for high-wear areas (e.g., mall corridors, airport lobbies). |

Stain Resistance | Good: Non-porous wear layer resists most stains (juice, ink). But if the wear layer is damaged, stains can seep into the decorative layer. | Excellent: Non-porous throughout—no layers to trap stains. Resists harsh chemicals (bleach, disinfectants) used in hospitals/labs. | Homogeneous is superior for high-hygiene or chemical-exposed spaces (e.g., labs, hospital ORs). |

Flexibility & Foot Feel | More flexible: Cushion layer (EVA foam) adds bounce, reducing foot fatigue. Ideal for spaces with prolonged standing (offices, retail). | Stiffer: Minimal flexibility (less plasticizer). Foot feel is firm, similar to tile. | Heterogeneous is better for comfort-focused spaces; homogeneous for areas where rigidity is preferred (e.g., industrial workshops). |

Repairability | Poor: Localized wear/scratches can’t be fixed—only entire planks/sheets replaced. | Good: Can be sanded, buffed, or refinished (up to 2–3 times) to remove scratches. Extends lifespan by 5–7 years. | Homogeneous offers better long-term value for spaces where replacement is costly (e.g., large hospitals). |

Dimensional Stability | Excellent: Fiberglass in the core/backing layer limits expansion (≤0.2mm/m·℃). Resists warping from moisture/temperature. | Good: Fiberglass mesh (if included) helps, but single-material design is slightly less stable (expansion ≤0.3mm/m·℃). | Heterogeneous is better for spaces with temperature swings (e.g., retail with large windows). |

Seamless Installation | Possible but limited: Sheets can be welded, but the layered structure may show slight seam visibility over time. Tiles are harder to weld. | Ideal for seamless installs: Single-layer material welds smoothly, creating a monolithic surface with no visible seams. Critical for hygiene (no crevices for bacteria). | Homogeneous is mandatory for spaces requiring seamless floors (e.g., hospital cleanrooms, food processing areas). |

Its balanced performance and aesthetic flexibility make it ideal for:

• Offices & Coworking Spaces: Cushion layer reduces foot fatigue for employees standing in meetings or at desks. Wood/stone-look designs create a professional vibe.

• Schools Commercial Vinyl Floor: Moderate wear resistance handles student traffic; soft foot feel is safe for children’s play. Custom patterns (alphabets, animals) add engagement.

• Retail Stores (Low-to-Medium Traffic): Boutique shops, clothing stores, or small cafes benefit from decorative designs that match branding—without the cost of natural materials.

• Hotel Lobbies & Corridors: Sound absorption (from the cushion layer) reduces noise from foot traffic; durable enough for guest use but not extreme wear.

Its through-color design and chemical resistance make it ideal for:

• Healthcare Facilities & Hospitals Flooring: Seamless installation prevents bacteria growth; resists disinfectants (bleach, hydrogen peroxide); scratch resistance maintains a clean appearance. Used in ORs, patient rooms, and labs.

• High-Traffic Vinyl Flooring & Transit Hubs: Mall food courts, airport terminals, and train stations need Class 5 abrasion resistance—homogeneous handles constant foot traffic and rolling luggage.

• Industrial Workshops & Labs: Resists oil, grease, and chemicals; rigid structure supports heavy equipment (e.g., tool carts).

• Public Bathrooms & Pool Areas: Non-porous surface and slip-resistant texture prevent water damage and slips. Seamless welds eliminate mold-friendly crevices.

se this checklist to align flooring type with your space’s needs:

Assess Traffic Volume: High-traffic (1,000+ people/day) → homogeneous; low-to-medium (200–500 people/day) → heterogeneous.

Prioritize Hygiene/Chemicals: If using harsh disinfectants or needing seamless floors (hospitals, labs) → homogeneous.

Value Comfort: Spaces with prolonged standing (offices, schools) → heterogeneous (cushion layer).

Aesthetic Needs: Custom patterns or natural material looks → heterogeneous; solid colors/subtle textures → homogeneous.

Long-Term Budget: If refinishing is better than replacement (large spaces) → homogeneous (lower total cost of ownership over 10 years).

Leave Your Message

Message us for free samples and quotes!