Stable commitment to every leap, customized every flat

Blog

Stable commitment to every leap, customized every flat

Blog

In school and kindergarten settings, commercial vinyl sheet flooring and interlocking flooring are the two main types of flooring materials, each with its own strengths in terms of safety, functionality, and suitability for specific scenarios.

Safety: Slip-resistant (reduce falls), formaldehyde-free / heavy metal-free (meets child contact standards), cushioning (reduce impact during falls).

Durability: Scratch-resistant (withstands furniture movement and toy dragging), stain-resistant (easy to clean juice, paint, and other stains).

Application suitability: Indoor (classrooms, activity rooms) require quietness and comfortable underfoot feel; outdoor (playgrounds, play areas) require weather resistance (UV resistance, water resistance).

PVC Commercial flooring is typically divided into two types: homogeneous and multi-layer composite. Homogeneous flooring has a wear layer and base layer molded as one piece, suitable for high-traffic areas (such as corridors and staircases), with a lifespan of 10-15 years. Multi-layer composite flooring consists of a wear layer, print layer, glass fiber layer, and base material, offering better elasticity, suitable for classrooms and libraries, with a lifespan of 8-10 years. Its thickness is typically 2-4mm, with the wear layer thickness required to be ≥0.7mm (commercial standard). The wear resistance can be preliminarily assessed through a key scratch test.

This vinyl sheet commercial flooring is suitable for various indoor areas in schools. The material itself has sound-absorbing properties, reducing walking noise by 20-30dB compared to tiles. It offers a wide range of patterns (customizable cartoon designs and educational theme textures), aligning with the playful atmosphere of kindergartens.

Homogeneous PVC: Excellent wear resistance, uniform color throughout, minor scratches can be sanded and repaired. Especially suitable for high-traffic areas (corridors, lobbies, staircases) and areas requiring regular deep cleaning/sanding (such as laboratories, kitchens).

Multi-layer composite PVC (LVT/Heterogeneous): Features a rich structural layer (wear layer, print layer, glass fiber stabilizing layer, foam/dense backing layer), offers realistic and diverse designs, and provides a more comfortable feel underfoot (especially with foam backing). It is the mainstream choice for classrooms, offices, and libraries.

Rubber flooring: Thicker, more elastic, better sound absorption, and extremely durable. Commonly used in gymnasiums (light use), special education classrooms (requiring better cushioning), stair treads, and laboratories (better chemical resistance). Typically more expensive.

Prioritize multi-layer composite PVC rolls (wear layer ≥0.5mm) for large-area installations; for small areas (e.g., bathroom entrances), choose sheet materials (for easy local replacement).

Environmental certification: Look for “halogen-free” and “low VOC” certifications (e.g., EU CE, French A+), and avoid low-cost recycled material products (which may release odors).

Abrasion resistance rating (T-class or AC-class): Schools must select commercial-grade or higher (T-class recommended at T-class or above, AC-class recommended at AC4/AC5).

Fire resistance rating: Must comply with local building codes (e.g., National Standard B1 grade).

Slip resistance rating (R value): Select based on area risk (corridors, staircases, entrances, and bathrooms require higher R values, such as R10/R11; classrooms typically require R9).

Environmental certification: Preferably GREENGUARD Gold or other stringent certifications.

Antimicrobial certification: Such as ISO 22196.

Sound absorption performance: Focus on the impact sound insulation improvement value ΔLw.

Adhesive full-surface installation: Most commonly used, offers the best stability, and achieves the best seamless effect (especially for homogeneous through-color flooring).

Quick-install: Fast installation, removable, suitable for substrates with excellent flatness. Commercial-grade locking systems must be selected.

Substrate Preparation:

The substrate (concrete or self-leveling) must be dry, sturdy, flat, clean, and free of cracks. Flatness requirements are extremely high (typically <2mm deviation within a 2-meter straightedge). An unsuitable substrate is the primary cause of future flooring issues.

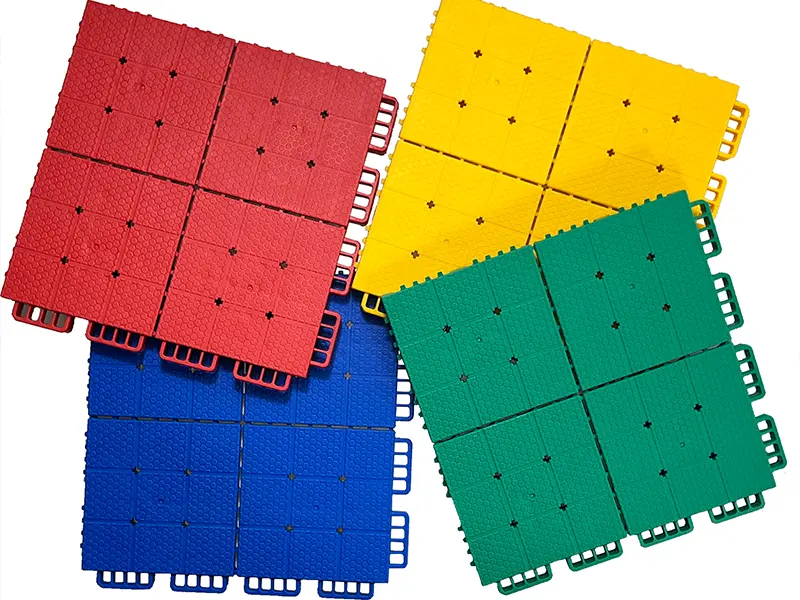

Interlocking floor tilesare the preferred solution for outdoor venues such as school playgrounds, basketball courts, badminton courts, activity areas, and pathways, renowned for their quick installation, excellent performance, and cost-effectiveness.

Polypropylene (PP): The most common, offering good value for money and balanced performance.

Modified PP/reinforced PP: Superior in weather resistance, strength, and low-temperature impact resistance, suitable for higher requirements or harsh climates.

Food-grade/environmentally friendly materials: Ensure safety and non-toxicity.

Single-layer solid: The most basic and economical option.

Cross-hatch/grid/double-layer hollow: Lighter weight, better drainage, and superior elasticity (especially the double-layer design), the mainstream choice.

Side connection methods: Snap-on (most common, secure), male/female groove, or lock-type. Ensure connections are tight, secure, and unlikely to loosen.

Support leg design: Height, density, and structure affect drainage, cushioning, and stability. Must match the base layer type (e.g., softer base layers may require denser support legs).

Thickness: Common thicknesses range from 8mm to 15mm+. For higher-intensity sports (e.g., basketball courts), thicker options (≥12mm or 13mm) are recommended for better cushioning and stability.

Unit weight: Typically positively correlated with durability and stability. Commercial-grade products have higher unit area weights.

Impact absorption rate: A core safety metric, should be ≥25%, with professional venues requiring higher values (e.g., ≥30%).

Vertical Deformation Rate: Reflects cushioning performance, typically within the 3–8mm range, requiring moderation.

Ball Rebound Rate: Basketball ≥90%.

Slip Resistance Coefficient/Anti-Slip Value: Complies with relevant sports venue safety standards (e.g., DIN 18032-2).

UV Resistance Rating: Ensures no fading or chalking over long-term use.

Although requirements are lower than for PVC flooring, the substrate must still be solid, flat, and well-drained.

Ideal substrate: asphalt concrete, cement concrete (expansion joints must be properly treated).

Acceptable substrate: highly compacted gravel/stone powder substrate (must be compacted with a roller).

Must be avoided: clay soil, sandy soil, loose or uneven substrates.

Leave Your Message

Message us for free samples and quotes!