Stable commitment to every leap, customized every flat

Blog

Stable commitment to every leap, customized every flat

Blog

Shengbang PVC sports floor material is popular for various indoor and outdoor ball sports fields. This material not only provides performance that meets competition requirements but also reduces procurement and subsequent maintenance costs. However, product quality varies greatly in the market. Inferior products often suffer from problems such as easily worn wear layers, foam layer collapse, and short lifespan. Therefore, careful selection of suppliers or manufacturers is crucial.

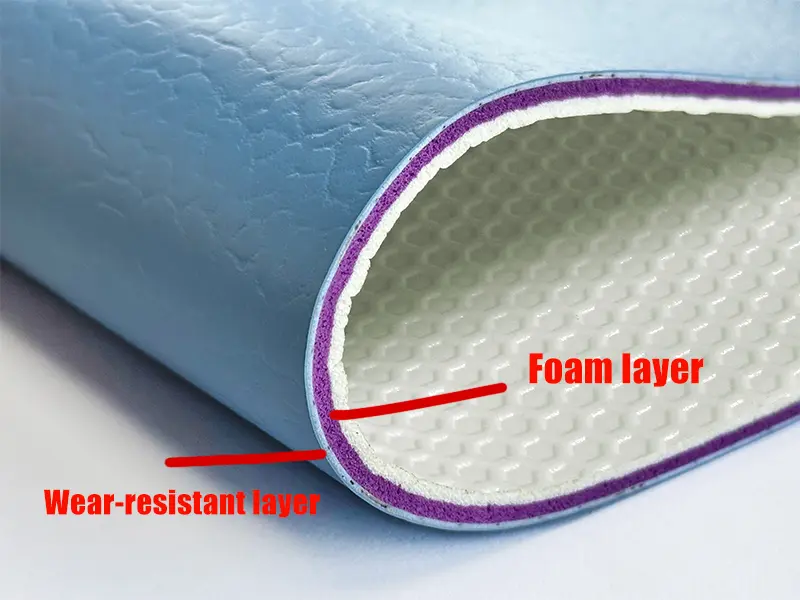

To choose the best PVC flooring rolls, focus on two core elements: the surface wear layer and the underlying foam layer. A simple and intuitive folding test can then verify the overall toughness and strength. I will combine our 30 years of flooring manufacturing experience with international standards to provide an authoritative explanation of how to judge the quality of sports flooring materials.

Watch on YouTube:

The wear layer directly determines the lifespan of PVC sports flooring—high-quality products can last stably for 8-12 years, while inferior products may show surface wear and expose the foam layer within 1-2 years.

A fundamental indicator of quality: Commercial-grade sports fields (gymnasiums, fitness centers) require ≥0.3mm; professional competition-grade fields require ≥0.4mm; ordinary training fields (school classrooms, community activity centers) require a minimum of 0.25mm. The thickness range is between 0.25mm and 0.7mm.

① Tool measurement: Using calipers with an accuracy of 0.01mm, measure at multiple points along the unpatterned edge of the floor sample and take the average value. High-quality products have uniform thickness with an error ≤0.02mm; inferior products often have uneven thickness, with some areas even lower than the labeled value.

② Visual comparison: Align the edges of two product samples. The difference in wear-resistant layer thickness can be clearly observed with the naked eye (as you mentioned, "significantly different thicknesses"). The thicker product is usually more durable.

③ Check the test report: As the manufacturer, we can provide a third-party test report, clearly indicating the wear-resistant layer thickness (EU EN 14411 standard).

Besides thickness, the wear-resistant layer of high-quality PVC sports flooring uses a "PUR (polyurethane) reinforced coating + nano-level wear-resistant particles (alumina, silicon carbide)," co-extruded at high temperature, resulting in a dense and smooth surface. This coating allows PVC vinyl flooring to be used in outdoor sports venues. Custom-printed flooring also uses a crystal armor surface layer to further improve waterproofing, slip resistance, and weather resistance.

The foam layer determines the elasticity and stability of PVC sports flooring. Inferior foam layers often have low density, poor strength, and insufficient elasticity, leading to issues such as collapse under foot traffic, irregular ball bounce trajectories, and even joint injuries to athletes due to insufficient cushioning.

Foam layer density: The higher the foam layer density, the denser the structure, the stronger the load-bearing capacity, and the less prone to collapse and deformation. High-quality PVC sports flooring typically has a foam layer density of ≥0.6g/cm³, with professional sports-grade products reaching 0.7-0.8g/cm³. Inferior products, on the other hand, often have a density below 0.5g/cm³, with large, unevenly distributed internal air bubbles and poor load-bearing capacity.

① Weight Comparison: Take two product samples of the same size (e.g., 20cm × 20cm) and weigh them. Assuming the same thickness, the high-quality product will be heavier due to its higher foam layer density; the inferior product will be significantly lighter.

② Cross-Section Observation: Cut the sample open and observe the cross-section of the foam layer. High-quality products will have uniform, fine air bubbles without obvious large pores; inferior products will have large, unevenly distributed air bubbles, and may even contain voids. Such products are prone to localized collapse after use.

③ Press Test: Press the foam layer firmly with your finger. A high-quality product will quickly rebound after being pressed, leaving no obvious dent. A low-quality product will rebound slowly after being pressed, and may even leave a permanent dent, which is a direct indication of insufficient foam layer density and loose structure.

Foam Layer Strength and Toughness: This determines the stability of the flooring after long-term foot traffic and localized stress (such as from sports equipment).

① Tear Test: Tear the foam layer at the edge of the sample. A high-quality product is difficult to tear even with considerable force, and the torn section is clean with no obvious stringing or looseness. A low-quality product breaks easily with slight force, leaving a rough section and scattered air bubbles.

② Load-Bearing Test: Lay the sample flat on a level surface and place a 5kg weight (such as a dumbbell) on it. After 24 hours, observe. A high-quality product will not show obvious dents; a low-quality product will show obvious dents that cannot be repaired.

③ Use the folding test: Regardless of the front or back, fold the sample in half by hand. The ease with which it breaks, turns white, and how easily it recovers its shape, as well as whether there are obvious creases or breaks after recovery, are the simplest and most intuitive judgment criteria.

For non-professional buyers, the most intuitive and effective quality verification method is the "folding test" mentioned above.

① Sample preparation: Cut a 10cm x 20cm product sample, ensuring neat edges and no damage;

② Front folding: Fold the sample with the surface (wear-resistant layer) facing inwards, aligning the edges. Press the folded area with your hand and hold for 3-5 seconds before releasing;

③ Back folding: Fold the sample with the back (foam layer) facing inwards, aligning the edges, pressing for 3-5 seconds before releasing;

④ Observation of results: Focus on the condition of the folded area—whether there is a sense of breakage, whitening, or whether it can return to its original shape.

“False Thickness Labeling”: The wear layer is labeled as 0.3mm thick, but the actual thickness is only 0.15-0.2mm. Verify this with calipers and check the test report.

“Secondary Bonding”: The surface wear layer and foam layer are glued on later. They easily separate by tearing the edges, and these products are prone to falling off after use.

“Fake Environmental Protection”: These products have a strong, pungent odor and lack proper environmental certification reports. Avoid them at all costs.

Judging the quality of PVC sports flooring focuses on inspecting the wear layer and foam layer, as well as verifying certification standards. The above simple and intuitive methods can be used to quickly verify this after purchasing and requesting samples.

For buyers, these methods can accurately avoid inferior products without requiring complex professional equipment. While high-quality PVC sports flooring has a slightly higher initial purchase cost, it has a long service life, low maintenance costs, and provides a safer and more comfortable experience for athletes, making it a cost-effective choice for long-term use.

Leave Your Message

Message us for free samples and quotes!