Stable commitment to every leap, customized every flat

Blog

Stable commitment to every leap, customized every flat

Blog

Traditional PP interlocking flooring typically uses independent block-shaped cushioning pads, which are sufficient for standard sports courts, including impact resistance, ball rebound, and player protection. However, for applications requiring higher durability for sports, training, and long-term use, such as in roller skating, ordinary modular flooring tiles are insufficient.

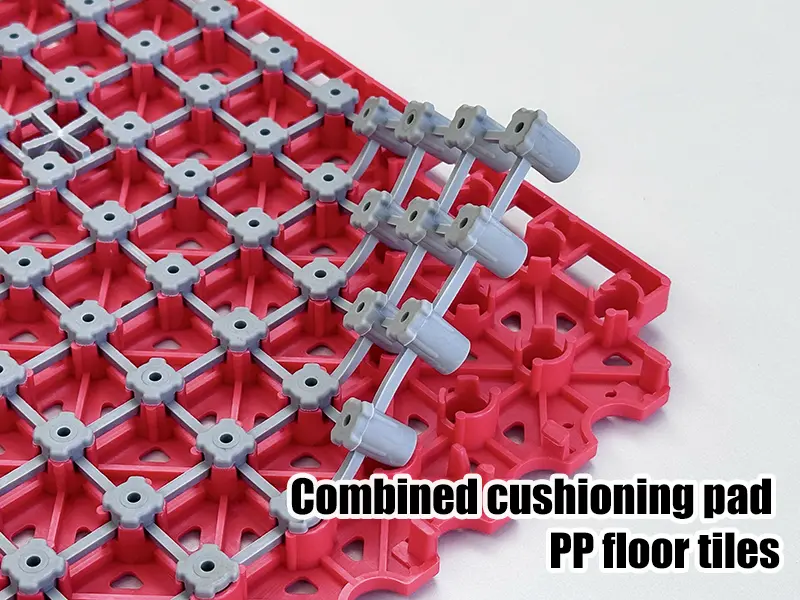

Therefore, we have optimized the structural design by using a through-type and combined connection method to add cushioning pads. This strengthens the connection between the PP tiles and the cushioning pads, greatly improving cushioning capacity and the stability between interlocking flooring tiles, thus extending service life. Based on this structural design logic, we, as the factory manufacturer, have produced different series to meet the requirements of various venues.

The core requirements for the surface in roller skating are smooth gliding, controllable elasticity, and stable grip. Traditional surfaces are prone to uneven gliding resistance and excessive impact when braking. This gray flooring with a fine porous structure retains its hydrophobic, perforated design while reducing resistance during skating, and provides sufficient grip during sudden stops to prevent skidding.

Outdoor sports flooring requires high weather resistance. Modified PP substrate and a through-type structure work together to withstand extreme temperature differences from -30℃ to 70℃. It adapts to thermal expansion and contraction through the locking mechanism and the deformation of the cushioning mesh. The hydrophobic structure can handle rain and snow accumulation, allowing for quick recovery and use, offering advantages over traditional plastic flooring and PP sports floor tiles.

Breaking away from the traditional discrete design of independent cushioning pads, this flooring uses high-density TPE elastomer as the cushioning material. An integrated injection molding process forms a closed-loop cushioning mesh. This combined design means that when a certain area of the floor is under stress, the load is no longer distributed at a single point, but rather through the integrated cushioning pad and floor structure, resulting in more even stress distribution and improved service life. This synergistic effect achieves consistent elasticity across the entire surface and seams, resolving the pain points of sudden stops on roller skates and bumpy surfaces at joints when children are running.

For outdoor temperature variations and deformation, there is also a continuous elastic pad structure. The continuous elastic columns, made of a modified blend of TPE and PP, are 8-10mm in diameter and run from beneath the anti-slip texture of the floor surface to the bottom cushioning mesh, forming a "column-mesh" three-dimensional support system. This strengthens the overall structural stability of the floor and improves the vertical cushioning continuity. The continuous structure effectively offsets the thermal expansion and contraction stress caused by changes in outdoor temperature and humidity, ensuring a dimensional stability error of ≤0.5% and fundamentally eliminating problems such as bulging and cracking.

If you are interested in modular Interlocking Sports Tiles and want to create your own professional outdoor project, we offer more than ten types of flooring models to choose from, precisely adapted to different venues, and provide the most cost-effective solutions.

Leave Your Message

Message us for free samples and quotes!