Stable commitment to every leap, customized every flat

Blog

Stable commitment to every leap, customized every flat

Blog

In professional basketball court construction, hardwood basketball flooring remains a primary choice, although vinyl sports flooring is now more cost-effective. However, the application of solid wood sports flooring in basketball courts requires careful consideration of usage frequency, environment, and installation and maintenance costs. The selection of solid wood basketball flooring should be tailored to its type, material, and manufacturing process to balance costs and improve efficiency.

This type consists of a single solid wood plank (20-22mm thick) directly fixed to the joists, without an additional cushioning layer. The wood grain is laid perpendicular to the ground. Key advantages: Relatively low cost, simple construction process, direct transmission of the wood's natural elasticity, suitable for basic training grounds or school gymnasiums with limited budgets. Performance: Impact absorption rate of approximately 25%-30%, ball rebound rate ≥80%, meeting the needs of basic basketball; surface wear resistance depends on the hardness of the wood itself, requiring regular waxing maintenance.

Limitations: The structure is simple, with limited cushioning performance. Long-term, high-frequency use can easily lead to board deformation and warping. It requires extremely high flatness of the subfloor; otherwise, it is prone to abnormal noise or localized dents.

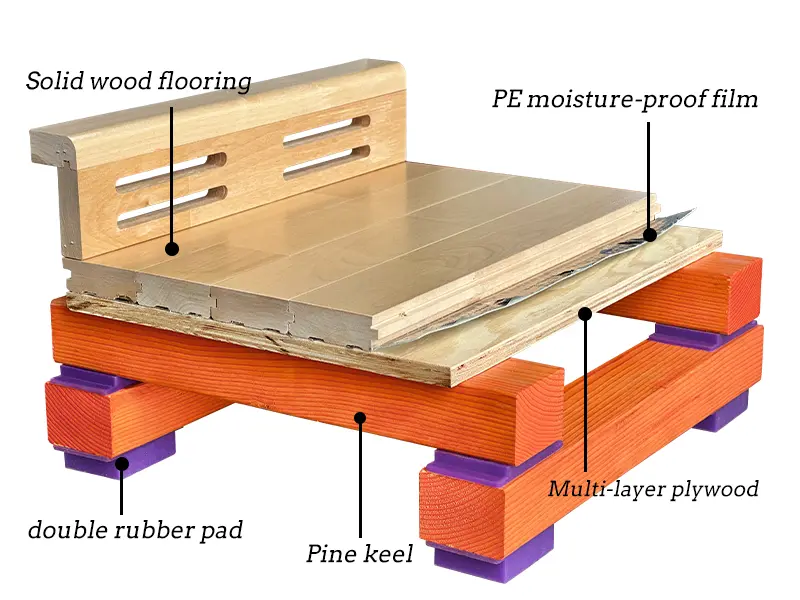

This type uses a composite structure of "face panel + subfloor + keel." The face panel is made of 20-22mm thick high-quality hardwood (such as maple or oak), and the subfloor is made of 12-15mm thick multi-layer board or solid wood. The keel spacing is 400-600mm. Some high-end models add an elastic pad (rubber or polyurethane material) between the keel and the subfloor to enhance cushioning.

Balanced athletic performance, with an impact absorption rate of 35%-45% (compliant with FIBA standards), effectively reducing the risk of joint injuries for players. The ball rebound rate is ≥85%, ensuring a stable basketball rebound trajectory, suitable for professional dribbling and shooting training. It can withstand more than 8 hours of high-frequency use per day; the elastic pad design further improves noise reduction, with an impact noise reduction of ≥18dB.

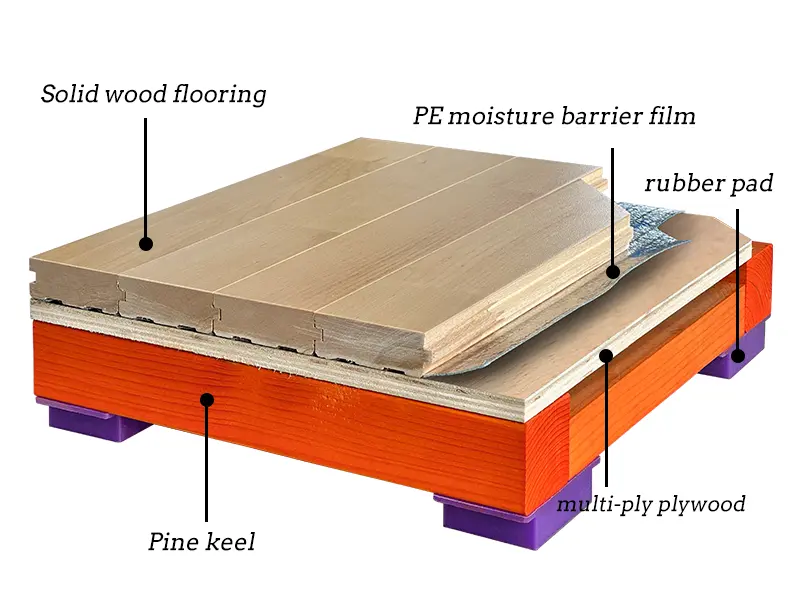

This flooring uses multi-layer solid wood composite boards as its base material (a 2-3mm hardwood veneer on the surface, and a core layer of fast-growing timber such as poplar and pine spliced together), with a total thickness of 20-24mm. It is fixed to the joists using a locking or adhesive method.

It offers high cost-effectiveness, balancing the athletic performance of solid wood with the stability of composite boards. The multi-layer cross-splicing design of the core layer results in a 30% lower coefficient of thermal expansion and contraction compared to single-layer or double-layer solid wood, making it suitable for areas with significant humidity variations. The surface hardwood veneer material can be selected according to needs, meeting different budget requirements.

Impact absorption rate is 30%-35%, ball rebound rate is ≥82%, and wear resistance is close to that of double-layer solid wood, resulting in lower daily maintenance costs.

Limitations: The core layer material has limited strength; long-term exposure to heavy equipment (such as moving basketball hoops) can easily lead to localized dents. The accuracy of motion feedback is slightly inferior to that of a pure solid wood double-layer structure. Suitable scenarios: Gym basketball areas, corporate employee activity centers, university gymnasiums (multi-purpose venues suitable for basketball and other sports).

The type of wood is the core factor determining the performance of solid wood basketball wood flooring. Priority should be given to hardwood species with high hardness, good elasticity, and strong wear resistance. Mainstream materials include maple, oak, beech, and ash, with maple being the preferred choice for top-level competitions.

Core Advantages: Moderate hardness (air-dry density 0.68-0.75g/cm³), excellent elasticity, balanced impact absorption and ball rebound performance; fine texture, small color difference, and uniform visual quality; outstanding wear resistance, with Taber abrasion test abrasion amount ≤0.1g/1000 revolutions; strong stability after drying, not easily deformed or cracked. Sub-types: Divided into hard maple (sugar maple) and soft maple. Hard maple has higher hardness (air-dry density 0.72g/cm³) and is the designated material for NBA venues (such as the Staples Center, home of the Los Angeles Lakers); soft maple offers slightly better value and is suitable for mid-range professional courts. Suitable Scenarios: Top-level competition venues, professional training bases, and high-end commercial basketball courts.

Core Advantages: High hardness (air-dry density 0.70-0.78 g/cm³), superior wear resistance compared to maple; clear and beautiful grain with natural mountain patterns, highly visually recognizable; 20%-30% lower price than maple, offering excellent value. Limitations: Slightly less elastic than maple, ball rebound rate is 3%-5% lower; relatively large color variation, requiring strict selection and grading of boards. Suitable Scenarios: University gymnasiums, amateur competition venues, mid-range commercial basketball courts (limited budget but seeking a hardwood feel).

Core Advantages: Extremely high hardness (air-dry density 0.75-0.80 g/cm³), strong wear resistance, suitable for high-frequency training venues; affordable price, only 50%-60% of maple; good stability after drying, suitable for basic training venues. Limitations: Less elasticity; impact absorption is 5%-8% lower than maple, potentially leading to joint fatigue from repeated jumping and landings; the grain is coarser, and the visual quality is slightly inferior to maple and oak. Suitable scenarios: Primary and secondary school basketball courts, community training grounds, and amateur basketball clubs (high daily usage frequency but limited budget).

Top-tier competitions (FIBA certification required, maple double-layer structure preferred), professional training (high wear resistance and elasticity required, maple or oak double-layer structure preferred), amateur use (cost-effectiveness preferred, multi-layer composite or beech single-layer structure preferred);

Usage frequency: ≤4 hours per day (single-layer or multi-layer composite structure), ≥8 hours per day (double-layer solid wood structure);

Environmental conditions: Areas with large humidity fluctuations (multi-layer composite structure preferred, or a temperature and humidity control system recommended), dry areas (single-layer or double-layer solid wood structure can be selected);

Impact absorption rate ≥35% (professional competition standard), ≥30% (training court standard); Ball rebound rate ≥85% (professional competition), ≥80% (training court); Coefficient of friction 0.65-0.75 (dry state). The air-dry density of the wood should be ≥0.65g/cm³ (ensuring hardness and abrasion resistance); moisture content should be 8%-12% (suitable for indoor environments, preventing deformation); surface board thickness should be ≥20mm (professional venue standard); formaldehyde emission should be ≤0.1mg/m³ (compliant with GB 18586-2008 standard), and vinyl chloride monomer content should be ≤5mg/kg, ensuring no odor or health hazards for indoor use.

It must undergo a dual process of "natural drying + artificial drying," with a moisture content error of ≤1% to prevent later deformation.

Abrasion resistance rating should reach commercial grade 34 or higher, with a matte surface finish.

The double-layer structure should use "elastic pad + keel" connection to enhance cushioning and sound insulation.

At least a 5-year warranty is provided.

Free installation and daily maintenance training is included.

Clearly defined material grades, process standards, certification document delivery time, and construction cycle are specified.

The core principles for selecting solid wood basketball court flooring are "scene suitability + performance priority + balanced cost-effectiveness." For basic training venues with limited budgets, choose a multi-layered solid wood composite structure (balancing performance and stability); avoid choosing single-layer, low-hardness materials to save costs (high maintenance costs and poor sports experience).

At the same time, it is necessary to strictly verify the wood material grade, craftsmanship details, and authoritative certifications, calculate the total cost over the entire lifecycle (not just focusing on the unit price of materials), and confirm comprehensive after-sales guarantees. Only in this way can you select solid wood basketball flooring that combines athletic performance, durability, and economy, providing players with a safe and professional sports environment while enhancing the professional quality of the venue and the brand image.

Leave Your Message

Message us for free samples and quotes!