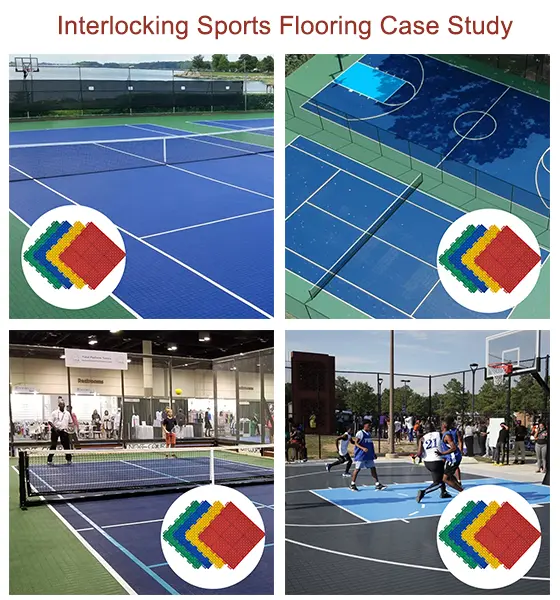

The DX22 model outdoor Interlocking sport court tiles features a nine-grid pattern, allowing you to choose your preferred color and size to install outdoor flooring that suits your site area and sports requirements.

Production Process

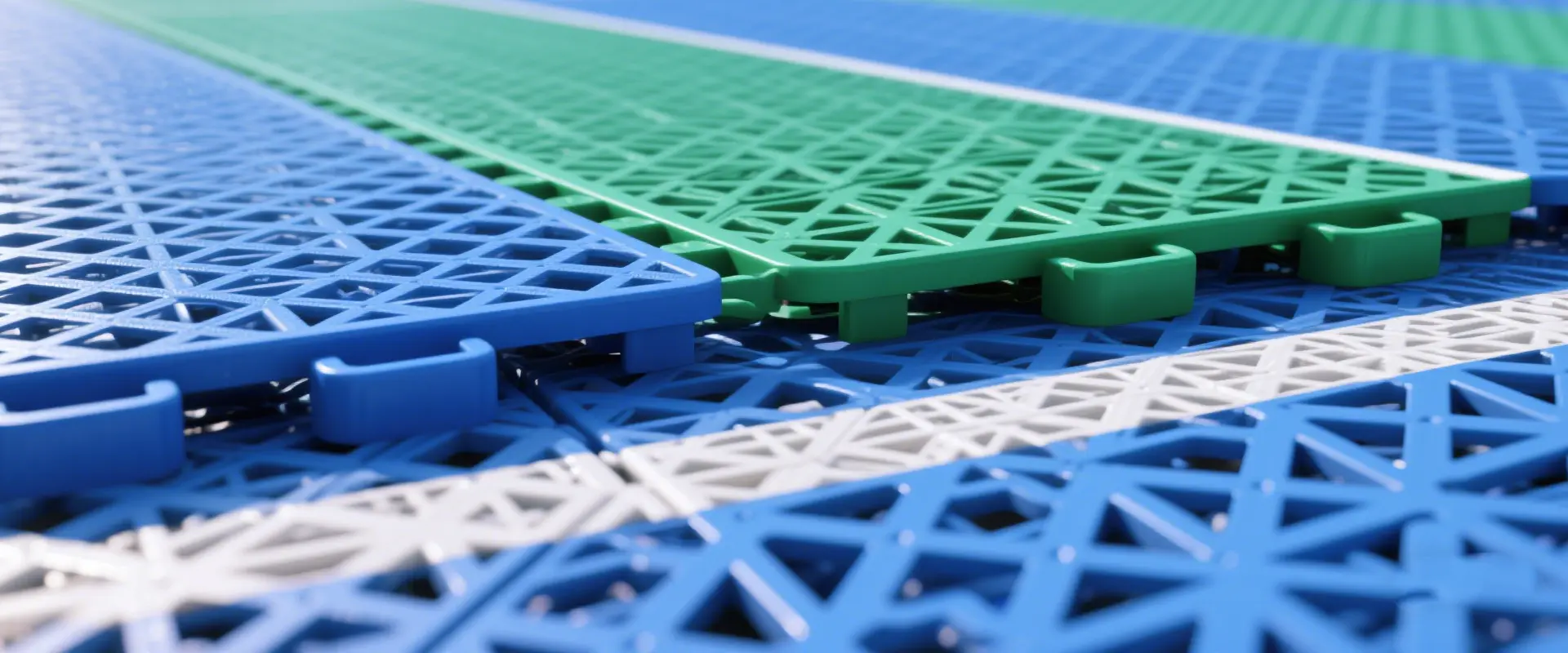

Our outdoor interlocking sports flooring utilizes advanced single-point injection molding technology, precisely molding raw materials in a single process to ensure the flooring's overall structure is robust, stable, and free of joints. This eliminates issues such as localized strength deficiencies or brittleness that may arise from multi-point injection molding.

The floor surface undergoes a special treatment process to create a smooth, textured finish, further enhancing slip resistance.

The edges are meticulously rounded, not only enhancing the aesthetic appeal of the flooring but also effectively preventing potential injuries caused by sharp edges.

From raw material procurement to finished product shipment, the entire production process adheres to stringent quality inspection standards. High-purity, high-impact-resistant, weather-resistant PP raw materials are selected and precisely blended with appropriate amounts of color masterbatch, UV stabilizers, antioxidants, flame retardants, and other additives. This creates high-quality, top-tier outdoor interlocking sports flooring.

Installation

The flooring uses a simple and intuitive locking system for easy installation, making the process as straightforward as assembling a puzzle. Even non-professionals can complete the installation in a short time, reducing construction time.

Whether it's a large-scale playground, sports field, or a small outdoor fitness area, the flooring can be quickly installed.

Comments