Stable commitment to every leap, customized every flat

Blog

Stable commitment to every leap, customized every flat

Blog

In hospital settings, the selection of flooring materials must balance safety (anti-slip, fall prevention), hygiene (waterproof, easy to clean, antibacterial), durability (suitable for high-frequency use), and comfort (quiet, elastic). PVC elastic flooring, due to its high-molecular material properties and design flexibility, has become the mainstream choice for hospital flooring. Solutions for anti-slip and waterproofing must be comprehensively constructed by integrating material design, construction techniques, and scene adaptability.

PVC vinyl flooring is primarily made from polyvinyl chloride (PVC), with additives such as plasticizers and stabilizers, and is manufactured through processes like calendering and extrusion, combining both elasticity and rigidity. For hospital applications, its core advantages include:

Elastic cushioning: Reduces the impact force during patient falls, lowering the risk of fractures;

Chemical Resistance: Withstands frequent cleaning with disinfectants (such as chlorine-based agents) and alcohol without fading or corrosion;

Easy Maintenance: Dense surface allows for easy removal of stains, meeting the high-frequency cleaning requirements of hospitals;

Sound Absorption: Reduces walking noise compared to tiles or stone, suitable for ward environments.

Hospitals are high-risk areas for slipping accidents (e.g., water spills in corridors, standing water in restrooms, damp floors after disinfection), so anti-slip performance must be ensured through a combination of “material design + scenario adaptation.”

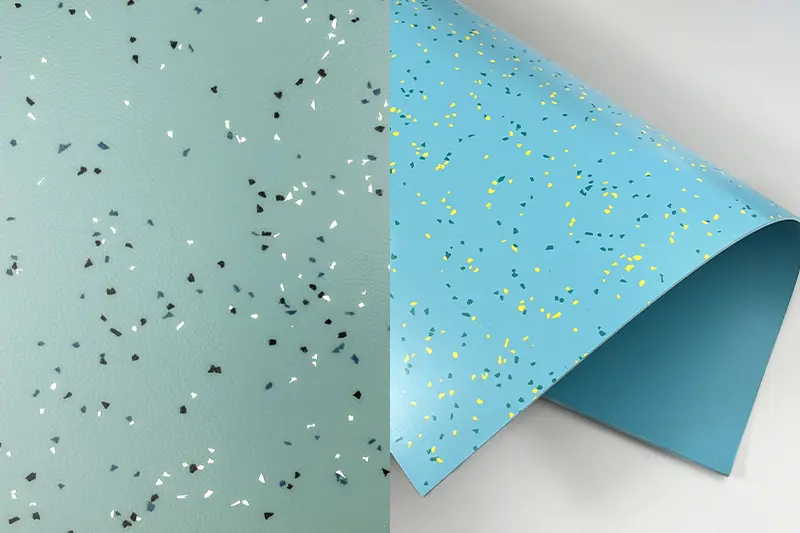

Rubber-plastic pattern highlights, typically using the homogeneous through-color structure and dense structure common in commercial flooring. Surface distribution of rubber-plastic mixed raised dots with diameters of 0.3-0.8mm to enhance friction and anti-slip performance.

Homogeneous texture without layering, with surface grooves up to 0.5mm deep that penetrate the surface layer, allowing for easy cleaning with a high-pressure water gun to prevent bacterial growth.

Homogeneous through-color vinyl flooring material offers superior chemical corrosion resistance, while the composite structure combines elastic anti-slip properties with sound-dampening cushioning.

Operating rooms / ICUs: Floors require frequent disinfection; homogeneous, transparent flooring is the preferred choice;

Hospital ward bathrooms: Commercial flooring with good elasticity and slip resistance is the preferred choice;

Outpatient halls / corridors: High foot traffic (including wheelchairs and stretchers); ensure stable friction in all directions of movement; choose commercial flooring with a PU coating.

Daily Cleaning: Use neutral cleaners (avoid acidic/alkaline agents that damage surface textures), and regularly clean dirt from textures with a soft-bristle brush (prevent oil buildup causing slippage);

Wear-Resistant Layer Protection: The surface is coated with a 2-3mm thick transparent wear-resistant layer (containing aluminum oxide particles) to resist long-term wear from stretchers and wheelchairs, preventing texture wear that reduces slip resistance.

PVC has a dense molecular structure and is a non-porous material (water absorption rate ≤0.1%). Its base material (multi-layer composite structure with a wear-resistant layer on the surface, a foam layer in the middle, and a stabilizing layer at the bottom) uses a waterproof formula, so it will not swell or penetrate even when exposed to liquids for extended periods.

The joints between floor panels are a weak point for waterproofing; if not properly treated, liquids may seep into the base layer through the seams. Medical-grade PVC flooring achieves complete seam sealing through thermal welding:

Welding rod selection: Use PVC welding rods made of the same material as the flooring (diameter 2-3mm) to ensure chemical compatibility;

Welding process: After laying the flooring, use a slot cutter to create a V-shaped groove along the seam (depth: 2/3 of the flooring thickness), then use a heat gun (temperature: 180-220°C) to melt the welding rod and fill the groove. After cooling, a sealed seam integrated with the flooring is formed, achieving a waterproof rating of IPX7 (no leakage even after short-term immersion);

As a major manufacturer of vinyl sports flooring and commercial flooring in China, our PVC-based elastic flooring fully meets the stringent safety and hygiene requirements of hospitals while enhancing the patient experience through its elasticity and sound-dampening properties, making it the preferred flooring solution for hospitals today.

Leave Your Message

Message us for free samples and quotes!