Stable commitment to every leap, customized every flat

Blog

Stable commitment to every leap, customized every flat

Blog

Basketball court maple flooring is a material that combines performance and design, making it a classic choice for professional basketball courts. The main materials available are basketball wood flooring and PVC basketball court flooring, with PVC materials also available in maple and oak wood grain patterns. For example, the commonly used yellow and black maple wood grain patterns not only highlight a premium design aesthetic but also offer cost advantages. If you are looking to renovate your basketball facility or are a sports center service provider purchasing flooring materials, this article provides a professional and detailed analysis of surface materials.

To illustrate the widespread use of PVC basketball flooring mat, we compare it with traditional solid maple wood flooring and rubber flooring, highlighting differences in performance, cost, and suitability for various scenarios.

| Comparison Dimension | PVC Maple Flooring | Maple Wood Flooring | Rubber Flooring |

| Core Material | Multi-layer composite PVC (with foam layer) | North American hard maple (single-layer / three-layer solid wood) | Natural rubber + synthetic rubber (dense / foam) |

| Elasticity & Shock Absorption | 40%-60% impact absorption (meets mid-high end standards) | 55%-70% impact absorption (professional grade) | 60%-80% impact absorption (excellent shock absorption) |

| Wear Resistance | 20,000-30,000 rotations (moderate) | 10,000-20,000 rotations (requires periodic sanding) | 30,000-50,000 rotations (high wear resistance) |

| Slip Resistance | Dry friction coefficient 0.5-0.6 (balanced) | Dry friction coefficient 0.6-0.7 (slightly rough) | Dry friction coefficient 0.7-0.8 (relatively rough) |

| Stability | Excellent resistance to temperature/humidity deformation | Poor (prone to warping/cracking) | Excellent but may shift during reinstallation |

| Maintenance Cost | Low (no waxing, easy cleaning) | High (wax 1-2x/year, sand every 5 years) | Moderate (dust-prone, needs frequent cleaning) |

| Visual Effect | High-definition maple grain (printed) | Natural grain, premium texture | Mostly solid colors/granular patterns |

| Suitable Applications | School gyms, training facilities | Professional venues (NBA, CBA) | Outdoor courts, high-intensity training |

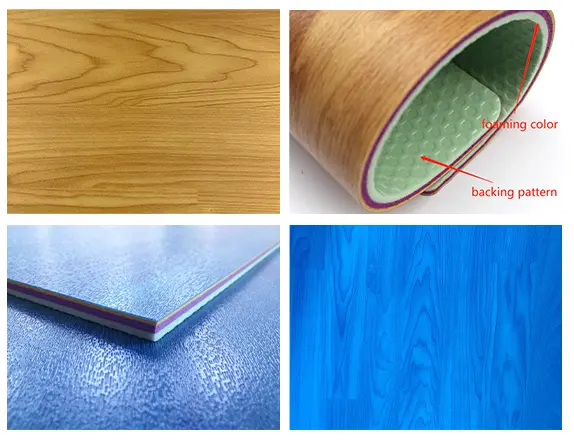

Made from 100% virgin PVC through a reasonable formulation process. The pure PVC structure ensures the floor's elasticity, flexibility, and long-term durability. The use of environmentally friendly plasticizers ensures it is free of formaldehyde, heavy metals, and other harmful substances, meeting ISO 14001 environmental management system certification standards.

High-definition printing technology replicates the texture and color of natural maple wood flooring, presenting a natural wood grain texture, creating a high-end and professional sports atmosphere for the venue. Different colors of maple wood can be selected to customize the basketball court, as well as logos and basketball court lines.

Common thicknesses include 4.5mm and 6.0mm or above, meeting the needs of daily and professional training scenarios.

Basketball flooring mats feature a five-layer structure, including a wear-resistant layer, foam layer, and fiberglass layer. This design meets the requirements for durability, rebound, and reflectivity needed for basketball. PVC basketball court flooring is lighter than wooden flooring, has lower installation costs, and meets performance requirements. It is easy to install and maintain, with low ongoing costs. Customized court patterns can be designed to suit indoor and outdoor needs.

The combination of natural wood properties and professional structural design maximizes compliance with the functional, safety, and experiential requirements of basketball for flooring. All wood must be “hardwood” (broadleaf trees) and must be “heartwood” (the central part of the tree trunk, which is more stable in material). Sapwood, due to its high moisture content fluctuations and tendency to warp, is strictly prohibited for use in basketball flooring.

Professional basketball wooden floors are not simply “solid wood panels laid out,” but a composite system comprising panels, joists, shock-absorbing layers, and moisture-proof layers. Their structural design directly determines their performance. Internationally, mainstream structures are categorized into three types:

Single-layer joist system (basic model): Suitable for training halls, school venues, and other medium-intensity scenarios, with lower costs.

Double-layer joist system (professional competition model): Suitable for professional league venues (such as CBA home courts) and professional training facilities.

Panel joist system (lightweight model): Suitable for venues with limited ceiling height (such as community sports halls), with performance between single-layer and double-layer systems.

The material requirements for wooden floors result in higher costs, and maintenance also incurs certain expenses. However, for professional competitions, it remains an excellent choice.

PVC material can be used as the floor surface for both indoor and outdoor use. Compared to indoor use, outdoor use adds a PUR or UV coating to enhance wear resistance and slip resistance, while also withstanding various weather conditions.

Additionally, for outdoor use, PP outdoor interlocking floor tiles are recommended, as they are easier to install and better suited to outdoor venue requirements.

PP Material: High hardness and impact resistance. Each floor tile is a square module (common specifications: 30cm × 30cm, 50cm × 50cm, thickness 1.2–2.5cm). Installation does not require adhesive, allowing for flexible and rapid installation.

| Comparison items | Outdoor floating floor | Outdoor PVC roll flooring | Concrete floor |

| Installation difficulty | Simple (glue-free assembly, can be operated by non-professionals) | Complex (requires full adhesive installation, dependent on professional team) | Simple (but requires hardening treatment, which takes a long time) |

| Maintenance costs | Low (local replacement, can be washed with clean water) | Moderate (overall cleaning, large-scale repairs required for damage) | Low (but prone to sanding, requires regular repainting) |

| Movement protection | Good (shock absorption and slip resistance) | Moderate (average elasticity) | Poor (hard floors can cause injuries) |

| Weather resistance | Strong (UV resistance, high and low temperature resistance) | Moderate (prone to cracking with prolonged exposure to sunlight) | Strong (but prone to weathering and sanding) |

| Service life | 5-8 years | 3-5 years | 10 years + (but requires frequent repairs) |

In summary, PVC maple wood flooring is a cost-effective alternative to traditional solid maple wood flooring. Through multi-layer composite technology, it balances durability, elasticity, and stability, making it particularly suitable for non-professional basketball settings. Its core value lies in achieving the dual requirements of “maple wood grain visual appeal + basic athletic performance” at a lower cost while reducing post-installation maintenance pressure.

Leave Your Message

Message us for free samples and quotes!