Stable commitment to every leap, customized every flat

Blog

Stable commitment to every leap, customized every flat

Blog

Badminton is a sport of speed, agility, and precision—where split-second movements, sudden stops, and quick lateral slides demand flooring that balances elasticity, slip resistance, and consistent ball rebound. Synthetic flooring materials have become the standard for both professional and recreational badminton courts, outperforming natural wood and concrete by adapting to diverse environments (indoor/outdoor), usage intensity, and budget constraints.

This guide breaks down the most popular synthetic badminton court flooring materials, their core features, pros and cons, and ideal use cases—aligning with the needs of facility managers, sports enthusiasts, and procurement teams searching for reliable, performance-driven solutions. We also reference BWF (Badminton World Federation) standards to help you identify materials that meet professional gameplay requirements.

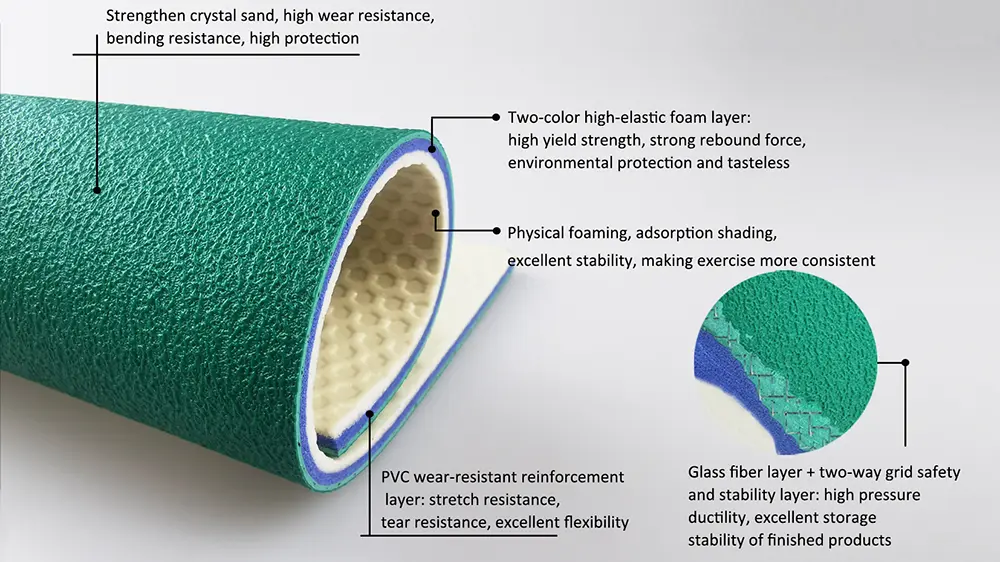

PVC (polyvinyl chloride) vinyl flooring is the most widely used synthetic material for indoor badminton courts, favored for its ability to replicate the feel of natural wood while offering superior durability and low maintenance.

Build: Multi-layered (wear layer + decorative layer + fiberglass stabilizer + foam underlayer) or single-layer (homogeneous) design, typically 3–6mm thick.

BWF Compliance: Meets BWF’s requirements for ball rebound (≥80% of natural wood) and shock absorption (20–30% impact reduction) when thickness is 4mm+.

Slip Resistance: Dry friction coefficient (COF) ≥0.65, wet COF ≥0.55 (EN 14411 R10), preventing slips during sweaty gameplay or minor spills.

Balanced Elasticity: Cushions landings to reduce knee/ankle strain, while maintaining enough rigidity for quick pushes and slides.

Low Maintenance: Non-porous surface resists stains, dust, and moisture—cleaning only requires sweeping or damp mopping (no waxing or refinishing).

Customizable: Available in wood, stone, or solid-color patterns; pre-printed court lines (singles/doubles boundaries) are fade-resistant.

Indoor Adaptability: Performs well in temperature-controlled environments (15–30℃) with minimal expansion or contraction.

Professional Installation Needed: Glue-down or hot-welded seams require skilled labor to ensure flatness and prevent edge lifting.

Not for Outdoor Use: Unmodified PVC degrades under UV exposure, leading to fading and brittleness.

Indoor badminton clubs, school gyms, community centers, and professional training facilities. BWF-approved PVC flooring is used in regional and international tournaments for its consistent performance.

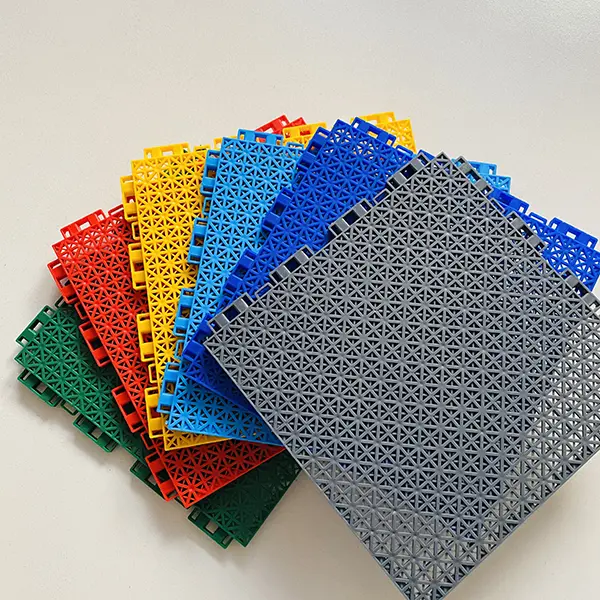

PP (polypropylene) modular interlocking tiles are a popular choice for both indoor and outdoor badminton courts, valued for their tool-free installation, portability, and resistance to harsh conditions.

Build: Rigid, single-piece tiles (30×30cm, 50×50cm, or 60×60cm) with interlocking edges, 18–25mm thick (including a hollow or foam core for shock absorption).

BWF Compliance: Entry-level to mid-range options meet recreational standards; premium PP tiles with enhanced cushioning (≥20% shock absorption) are suitable for semi-professional use.

Slip Resistance: Textured surface (e.g., diamond or ribbed patterns) provides dry COF ≥0.7, with some outdoor-rated tiles featuring anti-slip additives for wet conditions.

Tool-Free Installation: Interlocking design allows DIY setup in hours—no glue, nails, or heavy equipment required.

Outdoor Durability: UV-stabilized PP resists fading, moisture, and temperature extremes (-30℃ to 60℃), making it ideal for open-air courts.

Easy Replacement: Damaged tiles can be swapped individually without full-court renovation.

Multi-Purpose: Can be disassembled and reused for temporary events (e.g., pop-up tournaments) or multi-sport gyms.

Less Elastic Than PVC: Rigid core offers less shock absorption than PVC, which may increase joint strain during prolonged play.

Seam Gaps: Poorly installed tiles may have small gaps that trap dust or affect ball bounce (mitigated by choosing high-quality interlocking systems).

Outdoor recreational courts, temporary venues, schoolyards, and budget-conscious facilities needing quick installation.

Rubber flooring (natural or synthetic rubber) is a niche but valuable option for badminton courts prioritizing maximum joint protection—ideal for high-impact play, youth training, or facilities with frequent use.

Build: Solid rubber sheets or interlocking tiles, 4–8mm thick (indoor) or 10–20mm thick (outdoor), often with a textured surface.

BWF Compliance: Meets shock absorption standards (30–40% impact reduction) but may fall short of ball rebound requirements (70–75% vs. BWF’s 80% minimum) unless paired with a rigid underlayer.

Slip Resistance: Exceptional grip (dry COF ≥0.8, wet COF ≥0.7) due to rubber’s inherent traction, even with sweat or rain.

Superior Cushioning: Reduces impact force on knees, ankles, and hips by 30–40% compared to PVC or PP, lowering injury risk for young players or frequent users.

Sound Absorption: Dampens ball impact and footstep noise, making it suitable for multi-room gyms or residential basements.

Durability: Resists scratches, cuts, and heavy equipment (e.g., bleachers) without permanent damage.

Ball Rebound Inconsistency: Soft rubber can “deaden” balls, leading to slower rebounds that disrupt gameplay rhythm (solved by choosing rubber-polyester composite tiles).

Higher Cost: More expensive than PVC or PP, with higher shipping costs due to weight.

Maintenance: Porous natural rubber may stain if exposed to oil or harsh chemicals—requires regular sealing for outdoor use.

Indoor youth training facilities, rehabilitation centers, and high-traffic badminton clubs prioritizing safety over professional-level ball rebound.

PU flooring is a high-performance synthetic material designed for elite badminton courts, offering the closest feel to professional hardwood with unmatched durability and customization.

Build: Two-part liquid PU resin applied as a seamless coating (2–4mm thick) over a concrete or wood subfloor, often with a rubber granule underlayer for added cushioning.

BWF Compliance: Exceeds BWF’s top standards for ball rebound (≥85%) and shock absorption (25–35% impact reduction), making it a favorite for international tournaments.

Slip Resistance: Micro-textured surface provides consistent grip (COF ≥0.7) without hindering lateral slides.

Seamless Surface: No joints or gaps, eliminating tripping hazards and ensuring uniform ball bounce across the entire court.

Customizable Performance: PU formulations can be adjusted for elasticity (soft for training, firm for competitions) and color (including custom logos or court markings).

Long Lifespan: 15–20 years with proper maintenance, outlasting PVC and PP flooring.

Indoor Excellence: Resists moisture, mold, and UV damage (when used in covered facilities).

High Cost: 2–3x more expensive than PVC, with costly professional installation and curing time (24–48 hours).

Sensitive to Subfloor Quality: Requires a perfectly flat, dry subfloor (moisture ≤3%) to prevent cracking or bubbling.

Not for Outdoor Use: Vulnerable to rain and temperature fluctuations, which break down the PU resin.

Professional badminton arenas, national training centers, and high-end sports clubs willing to invest in tournament-grade performance.

Synthetic turf (artificial grass) is a specialized option for outdoor badminton courts, adapted to withstand weather elements while providing basic gameplay functionality.

Build: Short-pile turf (10–15mm) with a rubber or sand infill for stability, backed by a waterproof membrane.

BWF Compliance: Meets recreational standards but not professional requirements (ball rebound is 65–75%, below BWF’s 80% minimum).

Slip Resistance: Turf fibers provide natural traction, even in light rain (wet COF ≥0.6).

Outdoor Durability: Resists UV rays, rain, and extreme temperatures (-20℃ to 50℃) with minimal fading or degradation.

Low Maintenance: No watering, mowing, or resurfacing—only occasional debris removal.

Cost-Effective for Large Spaces: More affordable than outdoor-rated PP tiles for expansive courts.

Poor Elasticity: Harder than PVC or rubber, offering minimal shock absorption (increases injury risk during intense play).

Ball Rebound Issues: Turf fibers can slow or redirect balls, disrupting gameplay precision.

Infill Migration: Rubber/sand infill may shift over time, creating uneven surfaces.

Outdoor recreational courts, community parks, and schools with limited budgets for outdoor sports facilities.

| Material | BWF Compliance | Shock Absorption | Slip Resistance (Dry COF) | Indoor/Outdoor | Lifespan |

| PVC Vinyl | Yes (4mm+) | 20–30% | ≥0.65 | Indoor | 10–15yrs |

| PP Modular Tiles | Recreational | 15–25% | ≥0.70 | Both | 8–12yrs |

| Rubber | Recreational | 30–40% | ≥0.80 | Indoor | 12–18yrs |

| PU Flooring | Yes (Elite) | 25–35% | ≥0.70 | Indoor | 15–20yrs |

| Synthetic Turf | No | 10–15% | ≥0.60 | Outdoor | 5–10yrs |

Selecting the best material depends on 4 critical factors:

Professional/Elite Training: Choose PU flooring or PVC BWF-approved Badminton mat (4–8mm thick) for tournament-grade performance.

Recreational/Community Use: Opt for PP tiles or 3–4mm PVC for balance of durability and cost.

Youth Training: Prioritize rubber or thick PVC (5mm+) for maximum shock absorption.

Indoor: PVC, rubber, or PU (controlled temperature/humidity).

Outdoor: PP modular tiles or synthetic turf (UV and weather resistance).

Economical: Synthetic turf or basic PP tiles.

Mid-Range: PVC vinyl (most popular for value).

Premium: PU flooring (professional facilities).

Low Maintenance: PVC or PP tiles (minimal cleaning, no refinishing).

High Maintenance: PU flooring (requires periodic sealing) or rubber (occasional resealing for outdoor use).

For competitive play, ensure your synthetic flooring meets BWF’s key requirements:

Ball Rebound: When a standard badminton shuttlecock is dropped from 100cm, it must rebound 80–100cm.

Shock Absorption: The floor must absorb 20–30% of impact force (measured by a 2kg mass dropped from 50cm).

Slip Resistance: COF ≥0.65 (dry) to prevent slips during intense play.

Dimensional Stability: Maximum expansion/contraction of ≤0.5% under temperature changes (10–40℃).

Leave Your Message

Message us for free samples and quotes!