Stable commitment to every leap, customized every flat

Blog

Stable commitment to every leap, customized every flat

Blog

As a crucial material for professional sports venues, PVC sports flooring has become the designated material for international competitions in badminton, basketball, pickleball, table tennis, and other sports. With the global sports flooring market projected to expand at a CAGR of 4.9% from 2023 to 2030, this material, through continuous research and development, is increasingly tailored to specific user needs. As a manufacturer with over 20 years of experience in producing sports flooring, we have conducted research, based on relevant market data, on the impact of flooring structure and performance on the sports experience, to help sports facility builders and distributors make informed purchasing decisions.

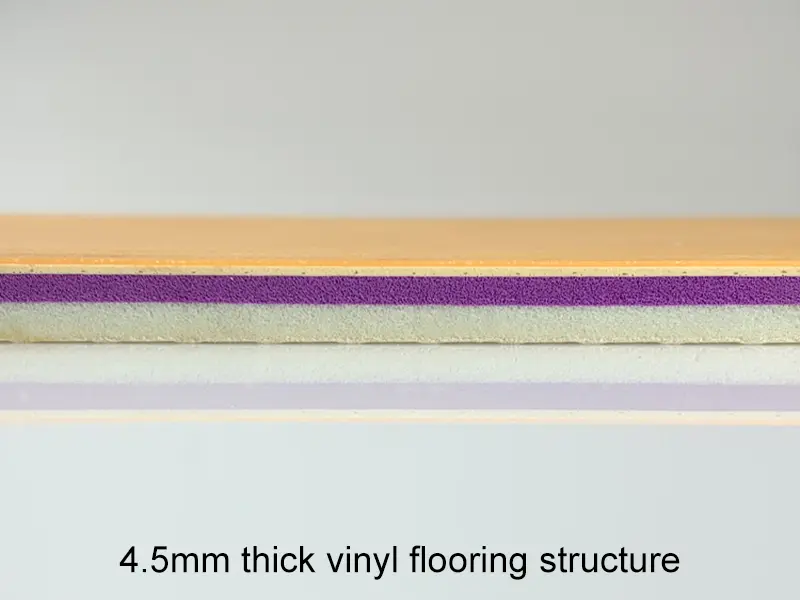

The thickness of PVC sports flooring directly determines its mechanical properties and suitability for various sports. According to international standards EN 14904 and ASTM F2825, the thickness typically ranges from 4.5-12mm, with specific performance differences as follows:

Impact Absorption:

4.5-5mm: Impact absorption of approximately 30-35%, suitable for lightweight sports like badminton and table tennis court. For example, the 5mm flooring used by Hebei University in China achieved an impact absorption of 30.8%, meeting the GB 36246-2018 standard.

6-8mm: Impact absorption increases to 35-45%, suitable for sports involving frequent jumping, such as basketball and volleyball courts. Dongxing's 9mm flooring achieves an impact absorption of 35-45%.

8mm and above: Impact absorption exceeds 45%, suitable for professional track and field and gymnastics, providing ultimate joint protection.

Vertical Deformation:

4.5mm flooring has vertical deformation ≤3.5mm, meeting the needs of indoor futsal and badminton courts.

7mm flooring has vertical deformation ≤2.5mm, meeting FIBA basketball court requirements.

Increased thickness improves impact absorption, but also reduces ball rebound. For example, 4.5mm flooring has a ball rebound rate of 95%, while 12.5mm flooring drops to 90%. The wear layer (0.7mm) of a 6.2mm thick floor can withstand over 10 years of normal use, while a 9.4mm floor (with an 0.8mm wear layer) is suitable for high-intensity sports events lasting over 20 years.

Conclusion:

When selecting sports flooring materials, thicker is not always better; it's crucial to consider the specific needs of the venue to achieve the best sports experience.

Traditional chemical foaming: Density 0.9-1.2g/cm³, resilience approximately 40-50%, low cost but prone to compression deformation over time.

Composite foam layer: e.g., EVA/POE/EPDM blend foaming, resilience up to 54.6%, 30% reduction in permanent compression deformation, suitable for high-intensity training.

ShengBang's calcium-free foaming technology (foaming through physical or improved chemical methods):

Supercritical physical foaming: Density can be reduced to 0.147g/cm³, resilience increased to 71% (e.g., LG Chem EVA/POE material), significantly reducing energy loss.

Closed-cell foaming technology: e.g., double-layer high-density foam, 30% improved resistance to indentation, residual indentation ≤0.5mm, suitable for equipment that is frequently moved (e.g., basketball hoops).

Foam density and elasticity: According to QB/T 2463.2-2018 standard, Type B foam layer (density 0.4-0.5g/cm³) has an elastic modulus of 24.5MPa, while Type C (0.5-0.65g/cm³) can reach 30MPa.

Conclusion: The foaming process and the use of calcium-free or low-calcium materials affect the actual resilience. Considering production cost and selling price, the type of foam layer should be determined based on the actual usage, such as high- or low-frequency sports activities.

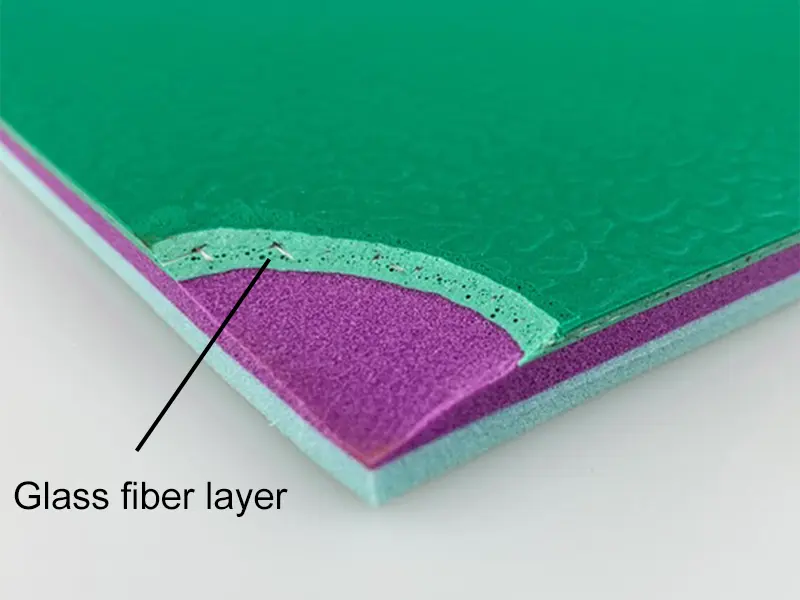

Single-layer fiberglass: Tensile strength ≥150N/cm, coefficient of thermal expansion 5-10×10⁻⁶/℃, suitable for environments with large temperature fluctuations. Double-layer fiberglass reinforcement: Tensile strength increased to 250N/cm, dimensional stability improved by 40%, and less prone to warping during long-term use.

There are dozens of different surface pattern designs for sports flooring, primarily affecting the coefficient of friction and slip resistance, which allows athletes to exert full power and perform various movements. Here are three common patterns:

Crystal sand texture: Coefficient of friction 0.65-0.7, excellent slip resistance, often used for badminton court flooring.

Litchi texture: Coefficient of friction 0.55-0.6, balances slip resistance and comfort, suitable for multi-purpose sports venues.

Gemstone texture: Coefficient of friction 0.5-0.55, smooth surface with excellent cushioning, suitable for sports requiring quick starts (e.g., volleyball), often used in various sports courts.

Wear Resistance:

Indoor PVC sports flooring typically has a UV coating to enhance wear resistance and reduce maintenance costs. Outdoor PVC flooring often uses PUR or crystal-clear surface coatings for even higher wear resistance.

| Sports Type | Recommended Thickness (mm) | Structural Design | Surface Pattern | Certification Requirements |

| Badminton/Table Tennis | 4.5-5mm | Single-layer Glass Fiber + Chemical Foaming | Crystal Sand Pattern | EN 14904, GB 36246-2018 |

| Basketball/Volleyball | 6mm 7mm 8mm | Double-layer Glass Fiber + Supercritical Foaming | Gem Pattern | FIBA, EN 14904 |

| Indoor Futsal Flooring | 6-8mm | Single-layer Glass Fiber + Composite Foaming | Lychee Pattern | FIFA, EN 14808 |

| Gymnastics/Athletics | 8-12mm | Double-layer Glass Fiber + High-Density Foaming | Matte Flat Surface | ISO 20345, ASTM F2825 |

Leave Your Message

Message us for free samples and quotes!