Stable commitment to every leap, customized every flat

Blog

Stable commitment to every leap, customized every flat

Blog

In international table tennis competitions, sports flooring directly impacts athletes' performance and the fairness of events.

According to official data from the International Table Tennis Federation (ITTF), less than 30% of table tennis court materials worldwide pass rigorous certification tests. These certified floors are essential for professional competitions and specialized training.

As a Chinese manufacturer with 20 years of expertise in sports flooring, Shengbang Sports Flooring Factory, in collaboration with Dongxing Plastic, leverages years of technical accumulation to achieve large-scale production of ITTF-certified products. We not only meet competition standards but also provide comprehensive solutions for numerous sports facility complexes!

The ITTF's certification standards for table tennis flooring are grounded in precise biomechanical research. As stipulated in ITTF Technical Manual T1, certified flooring must undergo comprehensive testing by officially recognized laboratories, meeting three critical performance metrics:

Ball rebound rate ≥92% (standard ball dropped from 30cm height must rebound ≥23cm);

Impact absorption within the 50%-70% range;

Vertical deformation controlled between 2.3mm and 5.7mm.

In dry conditions, the optimal range must be maintained between 0.5 and 0.6. Extensive testing confirms this value: below 0.5 causes slippage during sudden stops, while above 0.6 increases knee joint stress.

1. Utilizes “Three-Roll Dynamic Calendering + Instant Cooling” technology to form a uniform crystalline structure in molten PVC material, boosting tensile strength by 30%.

2. Each square meter undergoes 17 quality control procedures during production. Laser thickness gauges maintain dimensional accuracy within ±0.02mm—significantly exceeding the ITTF certification requirement of ±0.1mm.

3. Utilizes phthalate-free plasticizers and food-grade PVC resin, certified under EN14372 for children's product safety with formaldehyde emission levels below detectable limits (<0.01mg/m³).

4. Dimensions exhibit less than 0.1% change across temperatures from -30°C to 60°C.

5. The elastic foam layer features a closed-cell honeycomb structure, maintaining a consistent impact absorption rate of 62%.

1. Calculate the actual required floor area and add an extra 5%-8% for material wastage.

2. Inspect the venue's floor flatness (requiring a 2m straightedge measurement error ≤2mm), moisture content (≤8%), and subfloor strength (concrete substrate compressive strength ≥ C25).

3. Determine floor dimensions, thickness, and ITTF certification requirements based on venue usage frequency and purpose: sports arena? Competition venue? Activity center?

4. Bulk purchasing: For orders ≥500㎡, collaborating with manufacturers like ours typically offers greater discounts and customized solutions.

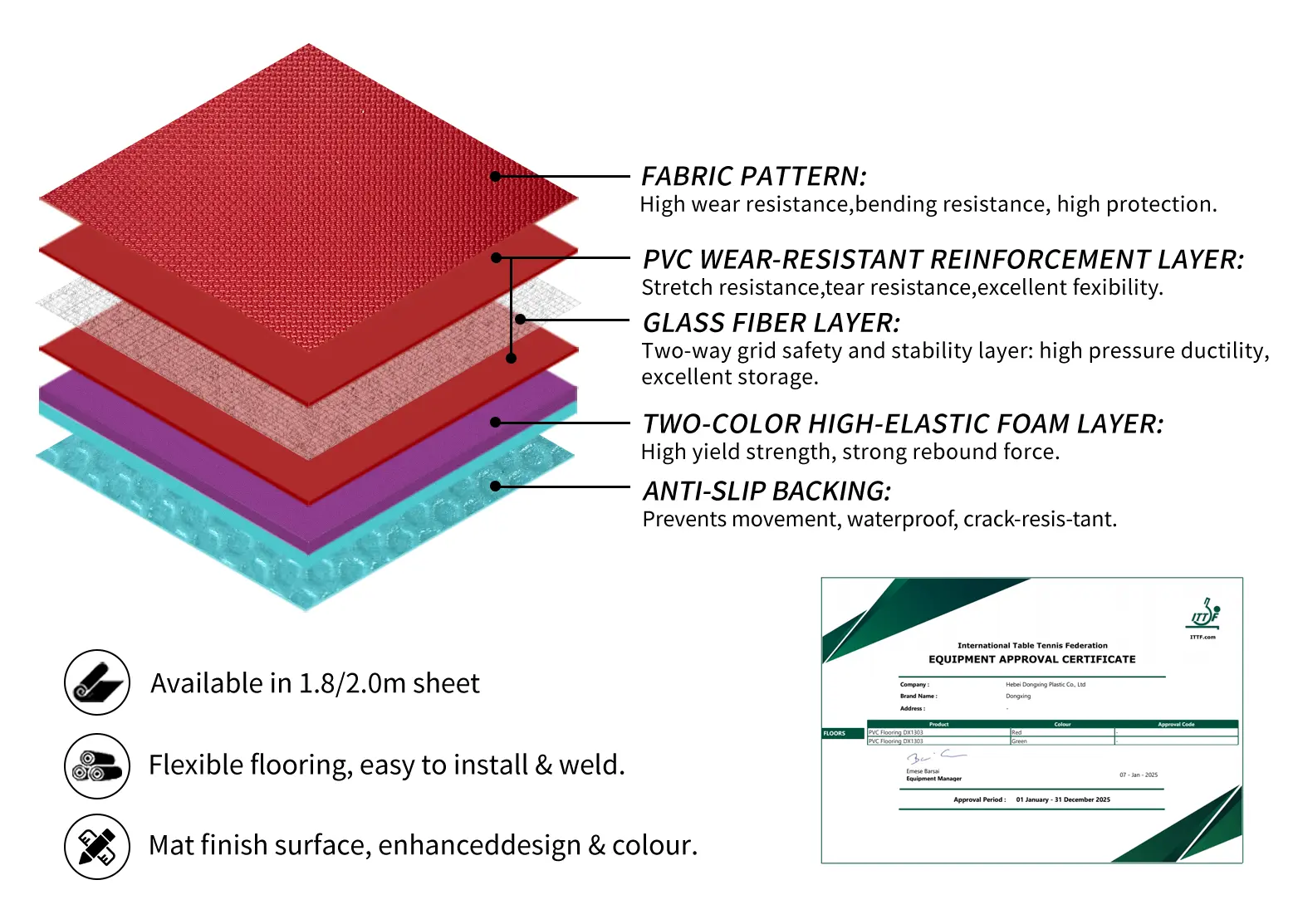

Recommended thickness: 4.5mm or greater. Composite structure comprising:

- Wear layer

- Glass fiber reinforcement layer

- High-density foam cushioning layer

Select 100% pure PVC material with a 1.5mm wear layer featuring anti-slip treatments like fine cloth texture or woven patterns.

Closed-cell foam structure: Higher density improves shock absorption. Recommended impact absorption value ≥50%.

Incorporate glass fiber mesh (single or double layer) to reduce thermal expansion/contraction deformation and enhance stability.

Ball rebound rate ≥90% to ensure consistent bounce and maintain playing feel.

Elastic recovery rate must be ≥90% to deliver responsive foot feel and athletic feedback, dependent on foam layer performance.

Friction coefficient must be controlled between 0.4-0.7 to prevent slip hazards.

Choose Shengbang Sports Flooring Manufacturer. We offer diverse specifications and solutions, supporting OEM/ODM customization for any dimensions, patterns, colors, or structures.

Leave Your Message

Message us for free samples and quotes!