Stable commitment to every leap, customized every flat

Blog

Stable commitment to every leap, customized every flat

Blog

For outdoor basketball courts aiming to meet both recreational and competitive standards, flooring material selection is paramount. Unlike indoor installations, outdoor surfaces must withstand weather impacts, demanding superior quality, abrasion resistance, and drainage performance. As a partner of Dongxing Plastics, China Shengbang Sports Flooring Manufacturer offers the following solutions for outdoor sports flooring construction:

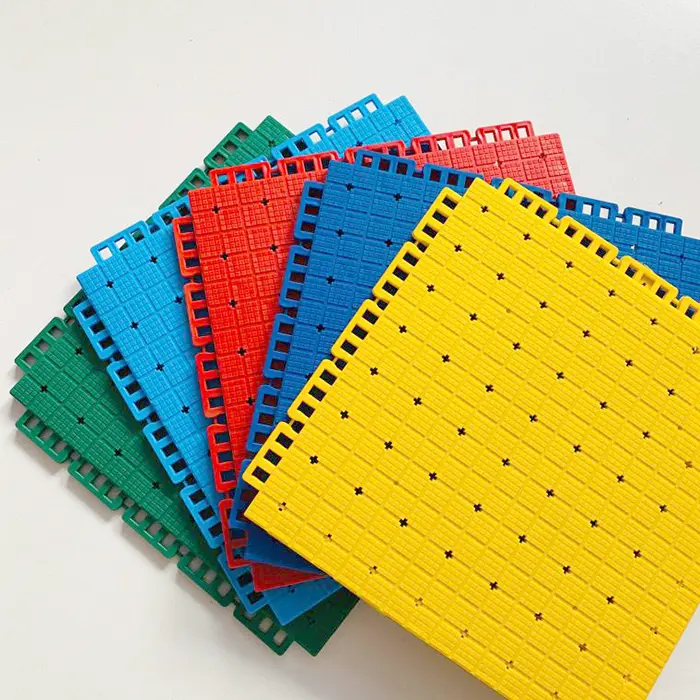

Recommended Outdoor Sports Flooring: PP Interlocking Floor Tiles

Manufactured using food-grade PP/TPE raw materials, certified by SGS EU RoHS, CE, and FIBA (International Basketball Federation). Temperature resistance (-30°C to 70°C) verified through field testing across 20+ global regions. Outdoor lifespan extends to 8-10 years, addressing climate adaptability challenges in high-temperature Southeast Asia and low-temperature Northern Europe.

We achieve zero-formaldehyde production throughout the entire process, utilising the world's leading eco-friendly equipment. Each batch comes with internationally recognised environmental testing reports, meeting public venue standards in Europe, America, the Middle East and beyond.

Individual basketball court tiles dimensions support custom specifications to accommodate varying national site size standards.

For instance, interlocking tiles measuring 30×30×1.38cm cover 10 square metres per 108 tiles.

Snap-lock connections require no adhesive for installation, enabling swift dismantling and reconfiguration to meet rapid assembly demands for temporary event venues.

The grid design achieves a drainage rate of 1.5L/(m²·s), enabling resumption of use within 30 minutes after heavy rainfall. This makes it particularly suitable for outdoor venues in tropical climates with high rainfall, such as Southeast Asia and South America.

Floor thickness can be customised to requirements, with optional underlay available in either hard or soft plastic materials to accommodate different levels of sporting intensity.

Friction coefficient: 0.5–0.7 (dry conditions), 0.4–0.6 (wet conditions). Each production batch undergoes friction coefficient testing with relevant reports available upon request.

Ball rebound rate: ≥85% (compared to solid wood flooring). Fully automated rebound testing ensures consistent performance across all panels, meeting international basketball training standards.

Impact Resistance: When subjected to a 10kg steel ball dropped from a height of 1m, the floor exhibits ≤2mm indentation without cracking. Third-party impact resistance test reports can be provided upon customer request.

1. Prepare the concrete foundation thoroughly.

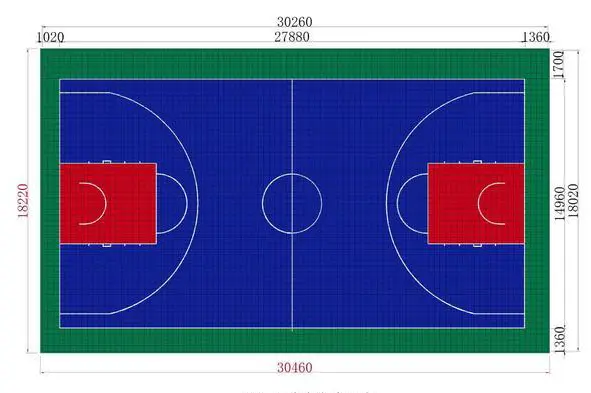

2. Outdoor basketball courts must strictly adhere to international standard dimensions (length 28m, width 15m, sideline width 5cm; precise positioning of centre line, free-throw line, three-point line, etc.).

3. Determine the laying direction; ensure consistent pattern orientation of floor blocks. For courts exceeding 500 square metres, incorporate transverse or longitudinal expansion joints at the centre.

4. Finish edges with trims to ensure alignment; trimming strips are supplied with our products.

Last,As a basketball court flooring supplier, we are delighted to provide tailored product solutions. Whether you are a sporting goods company, distributor, or venue constructor, please do not hesitate to contact us.

Leave Your Message

Message us for free samples and quotes!