Stable commitment to every leap, customized every flat

Blog

Stable commitment to every leap, customized every flat

Blog

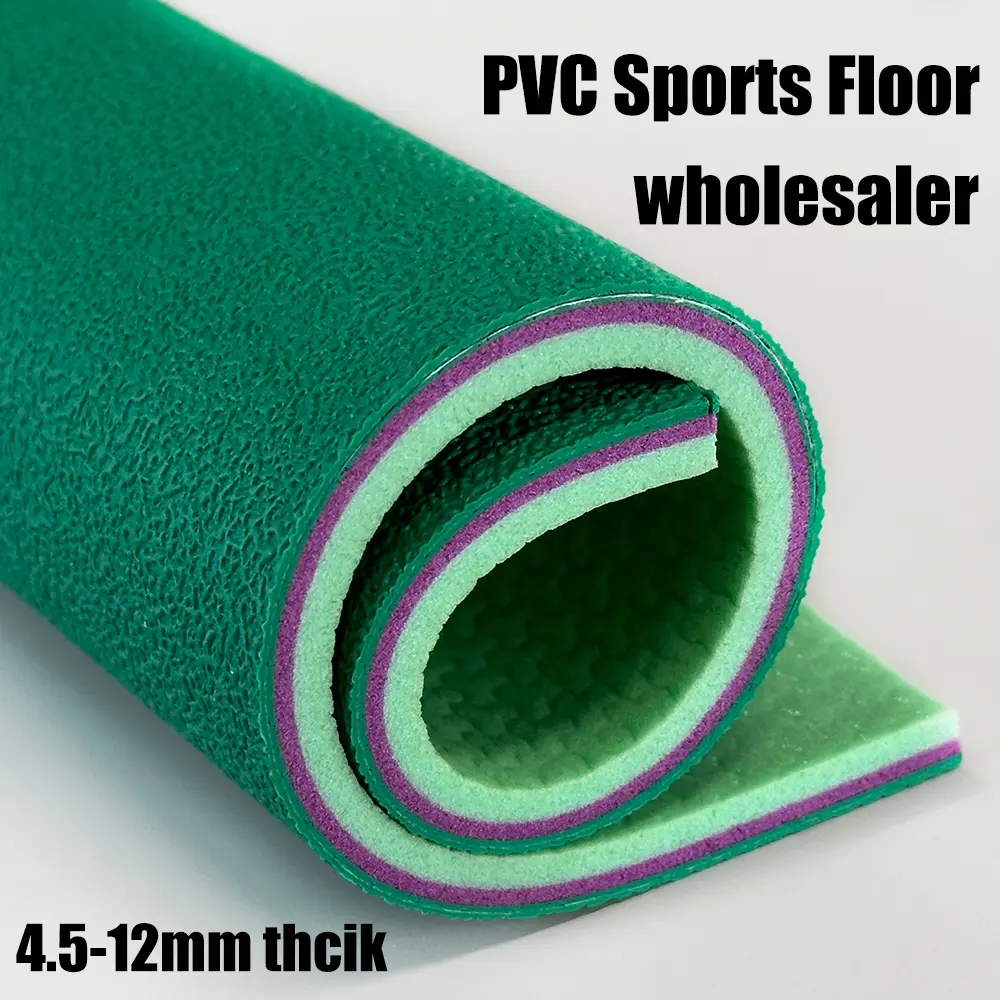

Our PVC vinyl sports flooring has been applied in many countries and regions in Europe, America, Asia, and Australia. After receiving the rolls, the most important issue for users is how to install them, especially for outdoor use. Correct installation even determines whether the sports flooring can be used for a long time without problems. Therefore, if you are building a venue for your sports project, this professional guide from a Chinese PVC sports flooring supplier can help you understand how to properly install and maintain it.

Suitable installation process: Weld joint adhesive application + welding installation.

The base layer for outdoor custom PVC sports flooring installation must be flat, dry, firm, free of dirt, protruding particles, and uneven.

Base layer and environmental testing:

(1) The height difference of the base layer expansion joints should be within 2 mm. If it exceeds this range, leveling and grouting treatment are required;

(2) The strength of the base layer should not be lower than the concrete strength C-20. Otherwise, it is recommended to use a suitable self-leveling compound to strengthen the strength;

(3) Use a hardness tester to test the hardness of the base layer. The surface hardness of the substrate should not be less than 1.2 MPa;

(4) The unevenness of the substrate should be less than 5 mm within a 2-meter straightedge range; otherwise, self-leveling compound is recommended for leveling;

(5) Use a thermometer and hygrometer to test the temperature and humidity. The ideal temperature for installation is 15-20℃. Installation is not recommended below 10℃, and cannot be done below 5℃. The relative humidity should be between 20% and 75%;

(6) Use a moisture meter to test the moisture content of the substrate. The moisture content of the substrate should be less than 3%.

Verification:

Verify that the quantity received matches the quantity shipped.

Sports Flooring Placement:

It is recommended to arrange the placement area reasonably before installation. Rolls of material should be placed vertically, and the placement area should be dust-free, sand-free, and protected from rain.

Verify the site dimensions against the installation design plan to ensure accuracy, and mark the flooring outline using engineering lines;

Refer to the rendering for pre-laying the flooring, placing the PVC rolls in the designated positions in an orderly manner, laying the boards according to their numbers, and trimming off any excess flooring after the pattern is neatly aligned.

Partial Fixed Installation (Glue Application at Floor Joints): Fold over approximately one-third of the width of two adjacent boards. Using the gap between the boards as the center line, evenly apply the special glue to the floor. After application, allow it to dry until it becomes tacky. (The glue application time should be controlled during the middle of the day.) Welding must be done during the hottest part of the day! Return the floorboards to their original positions, ensuring the joints are aligned, and repeatedly press until firmly bonded.

The remaining boards are installed in the same manner as above. Grooving and welding can begin one hour after installation.

Grooving: Adjust the grooving tool to the appropriate depth and cut a U-shaped groove along the board joint at a uniform speed.

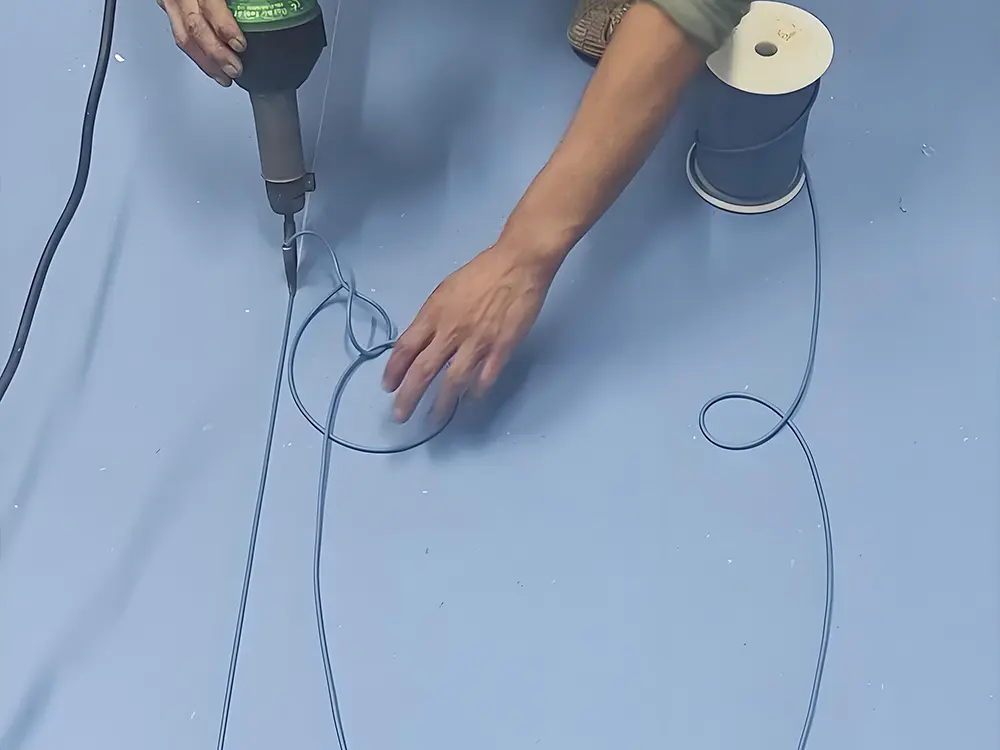

Welding:

(1) Use a welding torch to smoothly and evenly press the welding rod into the prepared U-shaped groove.

(2) After the weld line cools, use a weld line trimmer to remove the excess.

(3) Finally, check that each weld is secure.

For minor contamination such as dust and debris, simply rinse with water using a high-pressure spray gun.

For oil stains: For localized oil stains, apply undiluted degreaser directly to a towel and wipe. For large areas of oil stains, dilute the degreaser with water and clean with a multi-functional floor scrubber at low speed.

For adhesive or chewing gum: Apply a professional strong adhesive remover directly to a towel and wipe away.

Ensure proper drainage to prevent excessive water accumulation that could cause the floor to shift.

Avoid prolonged immersion of any part of the floor in water, as this can affect the overall appearance.

After snowfall, promptly remove accumulated snow to prevent it from freezing and cracking the flooring.

Do not use hard, rough cleaning tools (such as steel wool, knives, etc.) to clean the floor;

Take care during use, avoid piling heavy objects on the floor, dragging, and strong impacts;

Do not place heavy objects on the field to avoid problems such as bulging and shifting due to the floor's thermal expansion and contraction;

For areas with high traffic and significant wear, shorten the floor maintenance cycle.

Summary:

Shengbang manufactures professional indoor and outdoor sports flooring that meets international competition certifications such as BWF, ITF, ITF, ISO, and CE. We have over 20 years of experience producing PVC and acrylic sports flooring, continuously refining our production processes and technologies. We can provide customized solutions for your sports facility projects. Free samples are welcome!

Leave Your Message

Message us for free samples and quotes!