Stable commitment to every leap, customized every flat

Blog

Stable commitment to every leap, customized every flat

Blog

Choosing the right flooring material is crucial for the construction and upgrading of sports venues and infrastructure. While there are many sports flooring materials on the market, according to professional sports companies and experienced industry professionals, single-material flooring is no longer sufficient to meet the combined needs of professional competitions, daily training, and multi-functional reuse, and will soon be phased out.

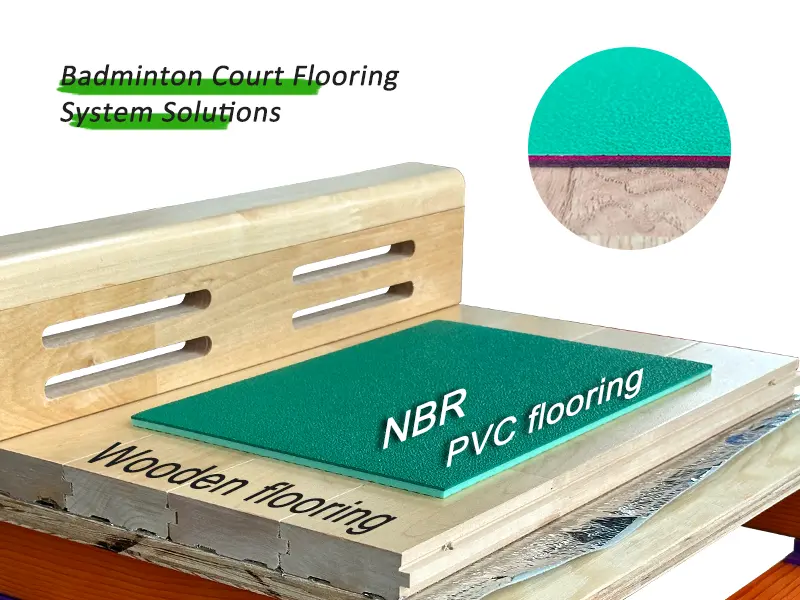

Some professional sports courts and stadiums utilize a combined system of "keel wood flooring subfloor + specialized PVC vinyl sports flooring surface" to create professional spaces. Leveraging its structural synergy advantages, this system has rapidly gained popularity in badminton courts, peak courts, gyms, and other venues, becoming the mainstream choice for sports infrastructure construction.

As a professional China sports flooring manufacturer, we have better control and more professional insights into materials, whether it's solid wood, PVC, or even acrylic, from raw materials to production. The combination of "keel wood flooring + PVC sports flooring" is not simply a matter of material layering, but rather a synergistic effect achieved through the complementary performance of the base and surface layers, resulting in a 1+1>2 synergy. Its main advantages are:

The keel wood flooring, as the base layer, uses solid wood or multi-layered solid wood substrate, and is constructed using a single, double, or triple keel structure to create an elastic support system. A high-quality keel system paired with a 5-10mm high-density elastic padding layer can achieve an impact absorption rate of 35%-53%, effectively absorbing ground reaction forces during exercise and reducing the risk of joint injuries. Industry test data from 2025 shows that a base layer using a double keel structure can achieve a vertical deformation of 2.3-3.0mm, fully meeting the professional competition standards of World Athletics.

PVC sports flooring typically features a 4.5-12.0mm thick surface layer, comprising a wear-resistant layer, a printed layer, a fiberglass stabilizing layer, and an elastic foam layer. Its ball rebound rate can reach 85%-92%. When combined with the subfloor, it can precisely match the varying elasticity requirements of different sports – for example, badminton requires rapid starts and stops, so the surface friction coefficient is controlled at around 0.45; pickleball requires moderate sliding, so the friction coefficient is adjusted to 0.50. This precise adaptation is impossible to achieve with wood flooring or a single PVC material on a concrete surface.

The PVC surface layer is completely hydrophobic, and the seams are seamlessly joined using a heat-welding process, providing waterproofing and preventing the underlying wood flooring from warping due to moisture.

The PVC surface features a PUR abrasion-resistant coating with added alumina particles, achieving a Taber abrasion resistance of over 15,000 revolutions. It can withstand high-frequency wear and tear from athletic shoe friction and equipment dragging. Market data from 2025 shows that this combined system has an average lifespan of 8-12 years in commercial stadiums, far exceeding the 5-7 years of solid wood flooring alone.

The integrated system of wood flooring and NBR layer PVC sports flooring can be quickly installed after the site's civil engineering is completed. Daily maintenance only requires wiping the PVC surface with a neutral detergent, eliminating the need for frequent waxing. Annual maintenance costs are only one-third of solid wood flooring, while performance and durability are significantly improved.

Single/Double keel base (8mm elastic pad thickness) + 4.5-5.0mm badminton-specific PVC flooring;

Impact absorption rate 45%-53%, ball rebound rate ≥88%, dry friction coefficient 0.43-0.47;

Single keel base (5mm elastic pad thickness) + 3.5-4.0mm Peak ball-specific PVC flooring;

Impact absorption rate 60%-65%, ball rebound height error ≤±5cm, wet friction coefficient 0.48-0.52;

Utilizing the high compatibility between Pickleballs and badminton court dimensions (doubles courts are both 13.41m×6.10m), this combined system can achieve "multi-purpose use of one venue." When renovating old venues, only the PVC surface markings need to be replaced, reducing renovation costs by 40%. By 2025, the proportion of such compatible renovation projects has reached [percentage missing]. 41.3%.

Three-joist elastic base layer (elastic padding thickness 10mm) + 5.0-6.0mm multifunctional PVC sports flooring;

Impact absorption rate 35%-65% (adjustable through padding), wear resistance grade AC6, supports multiple sports such as basketball, volleyball, and handball;

Base joists: Prioritize solid wood joists with a moisture content of 8%-12%, recommended materials are maple and oak, density ≥0.65g/cm³, elastic padding must meet international standards;

PVC surface layer: Possesses international certifications such as BWF, ITF, and FIBA, wear-resistant layer thickness ≥0.3mm, glass fiber stabilizing layer ensures dimensional stability and avoids deformation due to thermal expansion and contraction;

Environmental certification: ISO system certification, formaldehyde emission ≤0.124mg/m³, VOC emission ≤0.5mg/m³.

The flatness error of the concrete base layer should be ≤2mm/3m, the moisture content ≤8%, the keel installation spacing ≤400mm, and the elastic padding layer must be fully laid without hollow areas.

The PVC roll material uses a hot-welding process, with weld strength ≥80% of the base material strength; the sheet material uses interlocking splicing, with joint width ≤0.2mm.

Acceptance Testing: After construction, key indicators such as impact absorption rate and ball rebound rate must be tested, along with anti-slip performance testing (wet friction coefficient ≥0.5).

For venue builders and sports infrastructure companies, choosing this combined system not only meets current sports needs but also adapts to the development trend of "multi-purpose venues," reducing long-term operating costs.

Leave Your Message

Message us for free samples and quotes!