Stable commitment to every leap, customized every flat

Blog

Stable commitment to every leap, customized every flat

Blog

Glass fiber effectively improves flooring's dimensional stability, tensile strength, and durability. Currently, the market primarily offers single-layer and double-layer glass fiber constructions. We generally use double-layer glass fiber to ensure quality and performance.

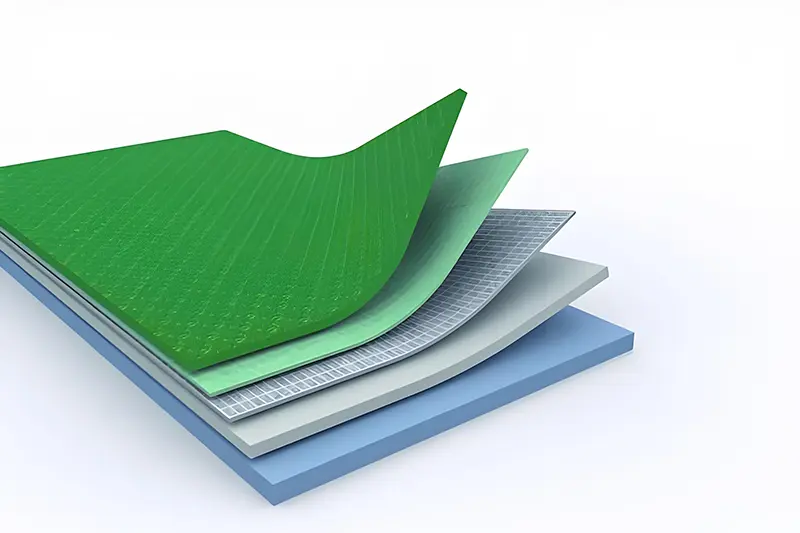

PVC sports flooring typically consists of a wear-resistant layer, a decorative layer, a glass fiber layer, a buffer layer, and a base layer.

The glass fiber layer's functions include:

Reducing thermal expansion and contraction of the PVC material due to temperature and humidity fluctuations, ensuring the floor remains flat over time and preventing warping and cracking;

Enhancing the floor's longitudinal and transverse tensile strength, preventing deformation under heavy loads (such as from running over sports equipment or athletes making sudden directional changes);

Evenly distributing impact loads from sports to the base layer, reducing localized stress concentrations and extending the floor's service life.

A single-layer glass fiber layer typically consists of a fiberglass mesh (typically weighing 160-200g/m2) embedded between the buffer layer and base layer of the PVC floor. This structure has the advantage of lower cost, but it also has significant drawbacks:

It only provides support in a single plane, limiting its ability to suppress three-dimensional deformation of the floor.

If the fiberglass layer and the PVC layer are not firmly bonded, delamination can easily occur, leading to localized wrinkling of the floor.

Double-layer fiberglass involves placing two layers of fiberglass mesh (total weight 240-300g/㎡) on the upper and lower sides of the PVC floor's buffer layer, creating a "sandwich" reinforcement structure. Our products utilize this technology, offering the following advantages:

Bidirectional three-dimensional support: The upper and lower fiberglass layers simultaneously constrain deformation of the PVC material longitudinally and transversely, improving dimensional stability by over 40%;

Uniform stress distribution: Impact loads are quickly transferred to the base layer through the two fiberglass layers, preventing localized damage;

Stronger interlayer bonding: The double-layer structure provides a larger contact area with the PVC layer, increasing bond strength by 30% and completely eliminating the risk of delamination.

The thermal shrinkage of single-layer fiberglass flooring is typically 0.3-0.5% (70°C, 24 hours), while the thermal shrinkage of Dongxing Plastic Double-Layer Fiberglass Flooring is controlled within 0.1-0.2%. This means that double-layer fiberglass flooring maintains better flatness over long-term use, making it particularly suitable for professional venues with extremely high flatness requirements (such as NBA-grade pvc basketball court fooring).

Tested according to ISO 527-2, double-layer fiberglass flooring achieves a longitudinal tensile strength of 18-22 MPa and a transverse tensile strength of 15-19 MPa, far exceeding the 12-16 MPa (longitudinal) and 10-14 MPa (transverse) values of single-layer fiberglass.

In practical scenarios, these advantages manifest themselves in:

It can withstand heavier sports equipment (such as basketball hoop bases weighing over 200 kg);

When athletes change direction at high speed, the floor exhibits no noticeable tensile deformation, ensuring safety.

Using the EN 14808 standard to test impact absorption, double-layer fiberglass flooring has an impact absorption rate of 25-30%, while single-layer fiberglass flooring only absorbs 20-25%. This means the double-layer structure can better cushion the impact of athletes jumping and landing, reducing the risk of joint injuries, making it particularly suitable for youth training venues and senior sports centers.

Under equivalent usage conditions, double-layer fiberglass flooring has a service life that is 3-5 years longer than single-layer flooring. Our project case studies have shown that gymnasium floors with double-layer fiberglass (such as the basketball hall of a middle school in Guangzhou) can provide stable service for over 10 years under an average of 8 hours of daily use, while single-layer fiberglass floors typically show noticeable wear or deformation after 6-8 years.

The tiny fiberglass layer plays a crucial role in the actual athletic experience. When choosing a vinyl sports flooring, consider whether its performance meets the requirements of the following international standards:

ISO 10581 "Resilient floor coverings — Determination of abrasion resistance"

This standard defines the test method for the abrasion resistance rating of PVC sports flooring and is the core basis for evaluating the floor's service life. For example, Class 5 (6,000 revolutions and above) PVC flooring is suitable for professional competition venues, and Dongxing Plastic's DX-Sport Pro series meets this rating.

EN 14808 "Sports floor coverings — Determination of impact absorption, vertical deformation, and ball rebound"

This standard specifies key sports performance indicators for sports flooring, including impact absorption (≥20%), vertical deformation (≤2.3mm), and ball rebound rate (≥90%). Dongxing Plastic's double-layer fiberglass flooring boasts an impact absorption rating of up to 30%, meeting the requirements of professional venues.

EN 14411 "Anti-Slip Performance Test"

In dry and wet conditions, the coefficient of friction (COF) test for PVC sports flooring requires a dry COF of ≥ 0.6 and a wet COF of ≥ 0.55 (R10 grade). Dongxing Plastic's micro-textured surface design meets this standard, making it suitable for use in high-humidity environments such as swimming pools and gyms.

Leave Your Message

Message us for free samples and quotes!