Stable commitment to every leap, customized every flat

Blog

Stable commitment to every leap, customized every flat

Blog

When selecting a high-quality PVC commercial flooring manufacturer, it is necessary to comprehensively consider multiple factors such as product quality, international certification systems, export experience, supply chain stability, technological innovation capabilities, cost-effectiveness, and service response speed.

Dongxing Plastic (China): Since 1996, the company has specialized in the research, development, and manufacturing of PVC sports flooring, interlocking flooring, and commercial vinyl flooring. It has obtained multiple certifications including ISO, CE, and sports event system certifications, and meets the commercial flooring standards corresponding to EN. Its products are designated for use in large-scale hospitals, shopping malls, transportation facilities, schools, and other sectors. As a 30-year-old established factory, it possesses a comprehensive manufacturing advantage across the entire production process, enabling rapid delivery of large-scale orders. Trust in Chinese manufacturing.

The top-level purification equipment used by Dongxing & Shengbang factories.

LG Hausys (South Korea): As a subsidiary of the LG Group, it features automated production lines and an international quality control system. Its PVC commercial flooring is renowned for its high-strength wear-resistant layer technology, offering a range of products including wood grain/stone grain residential styles and high-strength commercial rolls. These are widely applied in global commercial spaces such as office buildings, shopping malls, and hotels, with an export network spanning Europe, the Americas, and multiple Asian countries.

Armstrong (USA): A long-established global flooring giant, its Suzhou facility leverages advanced equipment to produce high-quality PVC flooring. Its product range includes elastic rolls and sheets, offering integrated floor-and-wall solutions, with a mature trade network in the Asian market.

Gerflor (France / Jiefu): Specializing in PVC flooring, it boasts strong R&D capabilities (such as eco-friendly plasticizer technology) and ensures product consistency through comprehensive quality inspections throughout the production process. Leading in niche areas such as antimicrobial roll flooring for hospitals and customized sheet flooring, compliant with fire safety and environmental standards like EN and GB, with a wealth of global project cases and a well-established international trade service system.

Forbo (Switzerland): A century-old sustainable development enterprise with a diverse PVC flooring product line that balances environmental sustainability and functionality. Products have obtained multiple authoritative certifications (such as EU REACH regulations and ISO certification), suitable for high-demand scenarios like healthcare, education, and commerce. The company has a mature global distribution network and strong trade compliance.

Tarkett (France): Focuses on innovative flooring solutions, with PVC flooring widely applied in high-traffic areas like airports and transportation hubs. The products excel in wear resistance and compression strength, backed by an efficient global supply chain and extensive export experience.

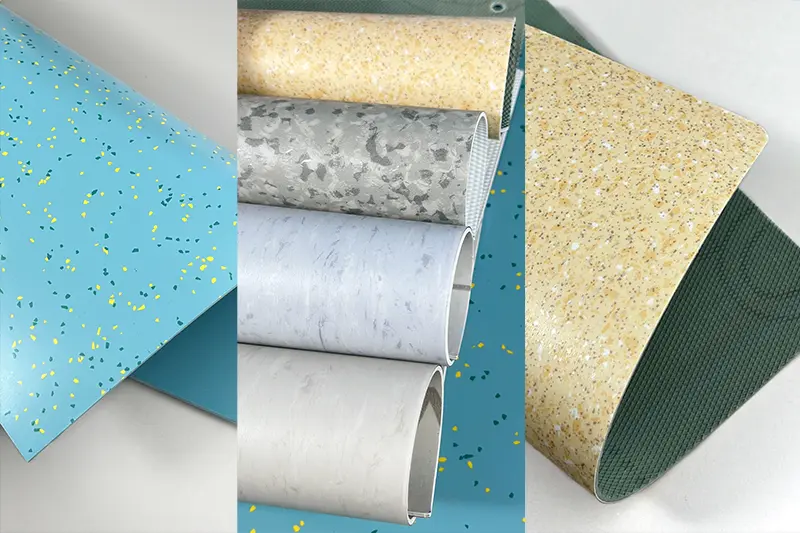

Commercial flooring must meet the demands of high-frequency use, wear resistance, ease of maintenance, safety and environmental protection, as well as customized functional requirements for specific scenarios. Currently, the two most widely used types of commercial flooring are homogeneous and composite structures, which mimic designs such as marble, stone patterns, and wood grain. We offer customization options (3D printing, personalized patterns) to meet the aesthetic needs of commercial spaces.

Performance requirements Taking our (Shengbang & Dongxing Plastic) vinyl sheet commercial flooring (multi-layer composite structure) as an example for reference:

| DESCRIPTION | STANDARD | RESULT |

| Total thickness | EN 428 | 2.0/3.0mm |

| Wear Layer Thickness | EN 429 | 0.25/0.35mm |

| Weight | EN 430 | 1750/2500/3300/4800g/m² |

| Width | EN 426 | 200cm |

| Length of sheet | EN 426 | 15/20m |

| Fire rating | GB 8624-1997 | GB 8624 Bf1 |

| VOC | GB 18586 | PASS |

| Dynamic coefficient of friction | EN 13893 | DS |

| Slip resistance | EN 51130 | R9 |

| Abrasion group | EN 649 | T |

| Castor wheel test | EN 425 | Suitable |

| Colour fastness | EN 20 105-802 | 6 |

| Chemical products resistance | EN 423 | Good |

| Dimensional stability | EN 434 | ≤0.40% |

| Flexibility | EN 435 | Excellent |

| Hygiene treatment | MRSA | Very Good |

| Impact sound reduction | EN ISO 717/2 | Approx.+4dB |

| Indentatio | EN 433 | =0.05mm |

| Residual indentation | EN 433 | Approx.0.04mm |

| Surface treatment | - | UV |

Leave Your Message

Message us for free samples and quotes!